I worked on the 430 when I first transferred to JD Lawn & Garden in '93. It was already in production then and my group was just launching it's replacement: the 455. The 420/430 still required engineering support though.

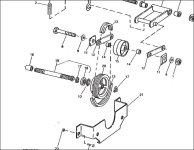

From memory, it had a Sundstand 90 transaxle and Yanmar 3TN72 diesel. It was one of the first garden tractors to get a diesel so air management was key (large amounts of cooling required in a small package). The Sundstand transaxle design dictated the engine rotation and thus orientation. It sucked cooling air in from the front and discharged below. The nose was extended out to add intake air surface. Too little screen and you build a vacuum cleaner that sucks airborne debris TO the machine. The engine was flipped on the new 455 and sucked cooling air in at the pedestal (the Kanzaki 90 transaxle was designed in conjunction). It too had minimal air intake area but brought air in closer to the operator. The debate still rages about which is better... you decide.

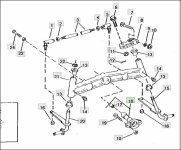

The 430 has proven itself to be a great tractor. What to look for though: 430 has Ackermann steering geometry controlled by a frame mounted steering cylinder... so the steering cylinder pushes the axle forward/back to facilitate turning. As steering components wear though, user inputs to the system get less and less precise creating steering that can feel "wonky". I don't remember if the 430 had axle outriggers for support (455 did). New bushings to tighten steering will fix.

I remember some (not crazy) muffler warranty! (because it was assigned to me!) Design guidelines always warn about mounting mufflers and intake canisters directly to engines... especially diesels! But in small packages (compacts on down) you have to. I recalled some failed warranty parts and saw the muffler failures: cracks at the header-to-can joint. I had Test order in some snazzy high temp stain gages and gaged up a new muffler. Installed on the several 430's we owned in Engineering... quiet. Low strain, no issues. WTH? A guy in Experimental told me though, his personal 430 had already cracked several. So with his backing, I had his machine picked up and brought to JD, gaged muffler installed, and tested. You guessed it... that stupid thing lit up like a search light! I had the engine guys go over it too... nothing wrong! Turns out, some desiels have a certain shake that others don't. I reinforced the muffler design as much as possible but a small percentage of machines could still fatigue one within their life.

Mower decks (especially the 60) on this machine were old designs and not considered great cutters. That's it... all I remember. I'm old.