J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,973

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

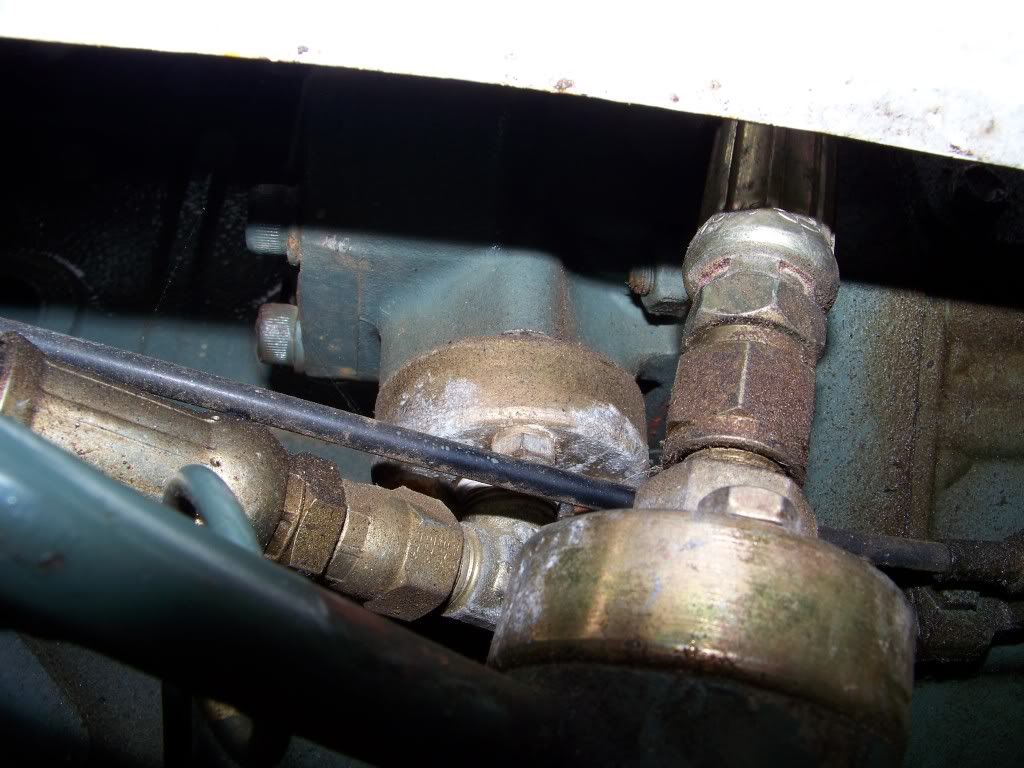

That dawned on me also that would bypass the filter this weekend thinking about how I am going to do mine for sure so the sump return is the best way.

I agree since basically most of the oil could be bypassing the filter thru the loader valve and right back in the inlet of the pump except when the loader valve is being operated.

I am wondering if there is some sort of slight restriction by going thru the 3pt the way these that are plumbed in series meaning it isn't a straight thru arrangement?

If there is that would most certainly could explain why there are some slow loaders out here.

I have a buddy that has a 2420D and his VN loader is plumbed with a bypass going into the sump and not in series with the 3pt. So I know for a fact not every single loader out there is plumbed in series fwtw some body somewhere is looking at this differently besides a few of us. My other friend that just bought a VN 1610D has a VN loader and I am not sure how its plumbed but I will be looking the first chance I get.

A slow loader is basically due to low volume.

There are valves with regen to speed up hyd flow. Have you seen a bucket with regen dump? Very fast.

Just about all return ports should go to the tank/reservoir. You can run a hose for each valve or tee several hoses together.

Open center valves pressure flow have to be connected in series unless you use something like priority valves to divide the flow, and then each flow has it's own path, but that path could have one valve or multiple valves, but must be connected in series to the tank.