Shield Arc

Super Member

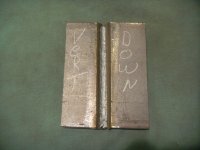

A member over on WeldingWeb sent me a roll of Hobart FabCOR CVN .045" Metal Core wire to play with:cool2:. I've never been around Metal Core before. Very fast wire. All I have for gas is 75% argon & 25% CO2. I under stand if you use 90% argon & 10% CO2 it's even faster. I started out with the V350-Pro set on Metal Core .045", but later switched to Standard CV Mig. I like that better. Does make a nice looking weld!

Product Details - Hobart Brothers Performance Welding Products

Product Details - Hobart Brothers Performance Welding Products

Attachments

-

MC Hobart.JPG225.4 KB · Views: 185

MC Hobart.JPG225.4 KB · Views: 185 -

MC first.JPG231.9 KB · Views: 218

MC first.JPG231.9 KB · Views: 218 -

MC second.JPG226.1 KB · Views: 245

MC second.JPG226.1 KB · Views: 245 -

MC CV1.JPG228.3 KB · Views: 182

MC CV1.JPG228.3 KB · Views: 182 -

MC CV2.JPG217.8 KB · Views: 202

MC CV2.JPG217.8 KB · Views: 202 -

MC CV3.JPG229.3 KB · Views: 175

MC CV3.JPG229.3 KB · Views: 175 -

MC etch cut.JPG237 KB · Views: 188

MC etch cut.JPG237 KB · Views: 188 -

MC etch.JPG226 KB · Views: 194

MC etch.JPG226 KB · Views: 194 -

MC *** 1.JPG231.3 KB · Views: 167

MC *** 1.JPG231.3 KB · Views: 167 -

MC hor2.JPG186.6 KB · Views: 209

MC hor2.JPG186.6 KB · Views: 209