OP

joshuabardwell

Elite Member

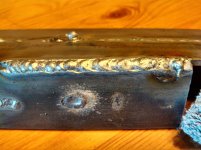

WOOT WOOT! After picking up my argon cylinder yesterday, tracking down all the gas leaks in my clamps, and figuring out (thanks to Mark @ Everlast) that I had forgotten to reverse my leads' polarity when switching to TIG, I finally got to put down some TIG welds with my PA160-STH today! I'm as excited as can be! One thing that I didn't realize about the unit, that is definitely worth mentioning, is that the finger switch is operable in both HF and lift mode. I realize this may be obvious to experienced TIG welders, but I didn't know it. I mistakenly thought that you had the choice of lift-start (where the finger switch activated the lift-sense voltage and broke the arc at the end) and HF with pedal. Currently, I plan to practice using the finger-switch only, with fixed output set on the panel. Since I'm working on steel (vs. aluminum), I suspect that modulating temperature halfway through the bead is not going to be as necessary, and I doubt that I have the sensitivity at this point to really know what I should be doing with the pedal anyway.