Richard

Super Member

- Joined

- Apr 6, 2000

- Messages

- 5,057

- Location

- Knoxville, TN

- Tractor

- International 1066 Full sized JCB Loader/Backhoe and a John Deere 430 to mow with

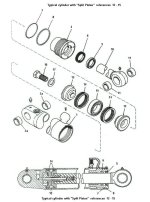

I've got a JCB 1550-B. Noticed the other day that the swing cylinders on the hoe are starting to leak. I've had the machine for maybe 10 years or so and have repacked (removed and taken to shop) virtually all the cylinders but for these two swing cylinders and the main cylinder for the hoe.

Poked my head back there and it looks like my presumptions are wrong.

I was presuming I could remove bolts A & B & C and slide the cylinder out so I could take it to the shop.

Doesn't look like it will be that easy.

Looks like I have four large bolts holding the bottom plate on (the plate that 'sandwiches' the cylinders and allows them to pivot left/right)

If this is accurate, it seems the entire assembly comes off which means it's going to weigh a ton and rip at least two of my fingernails off.

Anyone know if this is accurate?

If it is accurate, would I be better off trying to repack them myself (while staying on the machine) after buying or paying someone to make a large wrench so I can unscrew the ends?

I've done some internet searches and have only found some you-tube videos....bad thing there is something is wrong with this PC and it will not play a video at all. They turn to a snowy screen so, I've be unable to see any of them showing how it's done.

Thanks for any thoughts!

Poked my head back there and it looks like my presumptions are wrong.

I was presuming I could remove bolts A & B & C and slide the cylinder out so I could take it to the shop.

Doesn't look like it will be that easy.

Looks like I have four large bolts holding the bottom plate on (the plate that 'sandwiches' the cylinders and allows them to pivot left/right)

If this is accurate, it seems the entire assembly comes off which means it's going to weigh a ton and rip at least two of my fingernails off.

Anyone know if this is accurate?

If it is accurate, would I be better off trying to repack them myself (while staying on the machine) after buying or paying someone to make a large wrench so I can unscrew the ends?

I've done some internet searches and have only found some you-tube videos....bad thing there is something is wrong with this PC and it will not play a video at all. They turn to a snowy screen so, I've be unable to see any of them showing how it's done.

Thanks for any thoughts!