RonMar

Elite Member

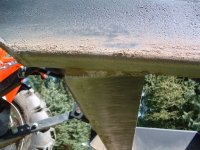

I got ambitious this week and put together the steel I had been collecting for a 60" grader box. I modeled it after a "Bad-Boy" grader.

The sides are 2" X 10" X 3/16" box tube with 3" heavy wall pipe for the forward cross where the 3PH attaches to. Blades are 4" X 4" X 1/4" angle with a 1/4" flat plate welded across the bottom forming a triangular tube. I followed Letsroll's lead and the forward cutting edge protrudes 3/4" below the sidewalls and is weld hardened with many repeated MIG passes(about 50' worth that are ground down into a cutting edge. The botom of the rear blade is flush with the sides.

that are ground down into a cutting edge. The botom of the rear blade is flush with the sides.

It has a swing down rear gate that rests against the rear blade and allows me to fill the box and drag material cut by the front blade.

Used it for the first time today for about 3 hours and started carving a new turnaround and smoothing the drive for gravel. I didn't realize there were so many large rocks in my drive. This thing sure ripped them out, some as big as bowling balls. Only drawback so far is with the lower profile sidewall material I used(box tube was free), the rear blade with the cross tube over it can clog with clumps of sod. Loose soil and rocks up to softball size pass over it just fine.

Only thing I have left to do is put the slider on the angle tube that will hold the rear gate in the open position. I figure if I attach a line to this slider, I can drop the gate from the drivers seat with a pull on the line.

The sides are 2" X 10" X 3/16" box tube with 3" heavy wall pipe for the forward cross where the 3PH attaches to. Blades are 4" X 4" X 1/4" angle with a 1/4" flat plate welded across the bottom forming a triangular tube. I followed Letsroll's lead and the forward cutting edge protrudes 3/4" below the sidewalls and is weld hardened with many repeated MIG passes(about 50' worth

It has a swing down rear gate that rests against the rear blade and allows me to fill the box and drag material cut by the front blade.

Used it for the first time today for about 3 hours and started carving a new turnaround and smoothing the drive for gravel. I didn't realize there were so many large rocks in my drive. This thing sure ripped them out, some as big as bowling balls. Only drawback so far is with the lower profile sidewall material I used(box tube was free), the rear blade with the cross tube over it can clog with clumps of sod. Loose soil and rocks up to softball size pass over it just fine.

Only thing I have left to do is put the slider on the angle tube that will hold the rear gate in the open position. I figure if I attach a line to this slider, I can drop the gate from the drivers seat with a pull on the line.