gemini5362

Veteran Member

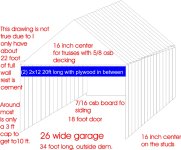

I am visually challenged when it comes to doing building in my mind. I flunked drafting so many times the instructor gave me a d so that I could get my degree. I am not sure that I understood your answer to my question, which means I probably did not compose it very well.

When you put your trusses up will they be running parralel with the garage doors or will the ends of the trusses be sitting on top of the header for the garage doors. The reason I am asking is because when I started researching the project I was going to do the two 2/x12 pieces of wood as headers. My 28 foot trusses have the end sitting on top of the headers. (not directly on top there is the top plates between them and the headers) everything i read on the web said that the 2 x12 double up would not carry the weight. I asked my neighbor who designs trusses for a living and he said it would not carry it. I went to a LVL beam to carry the weight. Each of my garage doors are 16 feet but it sounds like you are going to have similar issues if your headers carry the weight of the trusses.

We have finished framing and putting up the plywood sheathing around the framing. I got my trusses today and I am going to be installing them tomorrow If we come up with any easy way to do this I will post it

When you put your trusses up will they be running parralel with the garage doors or will the ends of the trusses be sitting on top of the header for the garage doors. The reason I am asking is because when I started researching the project I was going to do the two 2/x12 pieces of wood as headers. My 28 foot trusses have the end sitting on top of the headers. (not directly on top there is the top plates between them and the headers) everything i read on the web said that the 2 x12 double up would not carry the weight. I asked my neighbor who designs trusses for a living and he said it would not carry it. I went to a LVL beam to carry the weight. Each of my garage doors are 16 feet but it sounds like you are going to have similar issues if your headers carry the weight of the trusses.

We have finished framing and putting up the plywood sheathing around the framing. I got my trusses today and I am going to be installing them tomorrow If we come up with any easy way to do this I will post it