dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

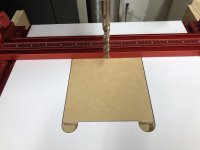

Thanks... this afternoon I got busy with the drill press table top. I bought a Woodpecker precision top but the increased table size interferes with the lift handle. Came up with a maybe brilliant solution at least in my mind. I wanted to be able to remove it quickly without threaded fasteners. Built a box that snugly fits over the cast table...^^^^ very nice, looks handy.

This elevates the surface and allows the crank handle to clear... well sort of... got to make a slight chamfer

My goal was not to hard fasten the box to the existing table, or the woodworking table to the box, so I created hardwood slides allowing me to move the table fore/aft as well as being able to swing it side to side thus utilizing more of the sacrificial inset backing plate.

This cubby hole is begging for a pull out low profile drawer... stay tuned!

The sliding table and sliding fence allow me to set zeros by multiple means. I think I have created a precision drill press table for woodworking that can come off quick simply by lifting it off the existing cast table for metal work.

Still need to do some finishing, maybe edge banding or white paint to match the table top and make a pull out tray I think.