zmoz

Silver Member

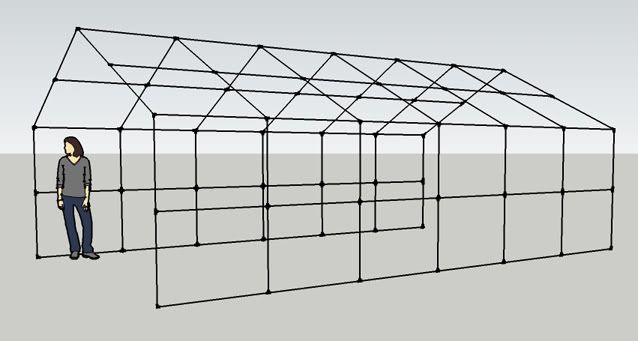

I am looking into building a *VERY* cheap metal shelter approximately 12-14' by 25'. It also needs to not be completely ugly.

I was thinking about getting a greenhouse hoop bender like this:

The Original Greenhouse Quick Hoop Bender "DIY" #DY-12 - eBay (item 150536230902 end time Mar-19-11 09:06:36 PDT)

Which uses standard galvanized chain link fence rails.

What I wonder is, could I make a bunch of hoops like that as if building a greenhouse, and then cover with coruggated tin roofing instead of plastic? Would it conform well to the curved shape, and would there be any structural issues?

I would prefer to bend the coruggated sheets 90 degrees across the corruggation for strength, but that would take a special bender. If I just use it lengthwise I would think it would be easy to bend around the curve.

Does anybody know where I could buy or possibly how I could make a bender that would bend the coruggated sheets 90 degrees to the coruggation? (like a culvert) Seems like this might be a much more structurally sound alternative....

I was thinking about getting a greenhouse hoop bender like this:

The Original Greenhouse Quick Hoop Bender "DIY" #DY-12 - eBay (item 150536230902 end time Mar-19-11 09:06:36 PDT)

Which uses standard galvanized chain link fence rails.

What I wonder is, could I make a bunch of hoops like that as if building a greenhouse, and then cover with coruggated tin roofing instead of plastic? Would it conform well to the curved shape, and would there be any structural issues?

I would prefer to bend the coruggated sheets 90 degrees across the corruggation for strength, but that would take a special bender. If I just use it lengthwise I would think it would be easy to bend around the curve.

Does anybody know where I could buy or possibly how I could make a bender that would bend the coruggated sheets 90 degrees to the coruggation? (like a culvert) Seems like this might be a much more structurally sound alternative....