mike69440

Elite Member

- Joined

- Jun 2, 2005

- Messages

- 3,362

- Location

- Central NH (God's Country)

- Tractor

- 2005 L39 Kubota, 2020 Polaris 570 Sportsman, 2006 RTV 900, 2019 RTV1100C, 1997 Komatsu PC75UU2E w/ Thumb & Blade, 2013 Mahindra Max28XL Shuttle plus many attachments

I'm looking a my options to obtain exact fit interchangeable up sized hydraulic cylinders for my tractor's loaders.

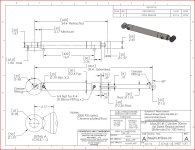

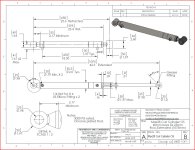

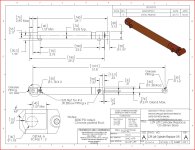

These will have to be custom built due to port location, that they are metric sized, and have non standard weird piston stroke and retracted lengths, as well as having metric pin bores.

The replacement DA Hydraulic Cylinders need to be 3000 # welded cylinders.

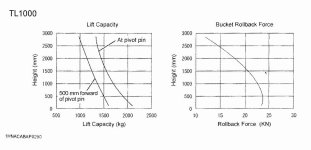

I have my two tractors that primarily want to increase the curl force on the attachment (Bucket attachment) cylinders. I would not mind also boosting the Lift a bit also.

Attached ismy spreadsheet on the info for the OEM cylinders and the up-rated version, just as an example.

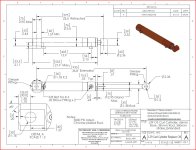

I'm making CAD models and details dimension prints also.

I have a few leads as to where I can source these, but want to first get an idea of the potetial quantity.

PM me if interested in doing a group buy or you just want a copy of the worksheet in Excel format.

These will have to be custom built due to port location, that they are metric sized, and have non standard weird piston stroke and retracted lengths, as well as having metric pin bores.

The replacement DA Hydraulic Cylinders need to be 3000 # welded cylinders.

I have my two tractors that primarily want to increase the curl force on the attachment (Bucket attachment) cylinders. I would not mind also boosting the Lift a bit also.

Attached ismy spreadsheet on the info for the OEM cylinders and the up-rated version, just as an example.

I'm making CAD models and details dimension prints also.

I have a few leads as to where I can source these, but want to first get an idea of the potetial quantity.

PM me if interested in doing a group buy or you just want a copy of the worksheet in Excel format.