DeereGirl

New member

I need some opinions from you guys. I'm new to the thought of using a log splitter of this type. I'm used to a standalone gas splitter. However, I have a barter opprotunity that sounds pretty good.

I have the opprotunity to pick up a Speeco 3 point Log Splitter. Here's the description that I've been given and pictures look really good:

"I bought this on CL a few months ago for $450 and only have split a half dozen logs. I believe I am the 3rd owner, but none of us has used it very much. The splitter is designed to operate using the hydraulic system of a class 1 or 2 tractor with a 3 point hitch system. Also, you could connect it to a stand alone hydraulic pump. It works perfectly. There is some deterioration on the covering of the 8 foot hoses but they do not leak. I installed a brand new "open" type hydraulic control valve ($140) and new quick release connectors ($40). It includes legs, but I have not used them. They seem to be selling new for about $850 (which may or may not include shipping). New they usually do not include hoses and connectors (+/- $100). "

My questions are as follows:

1. Are spitters of these types worth the money?

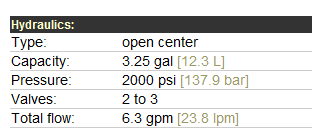

2. I understand that they work of the hydrolics of the tractor, will there be any reason why mine will not be able to handle it?

3. I'm sure there should be more questions asked but I'm not familure enough to know which ones. Is there something else that I should be thinking of?

Here's a PIC:

Any help would be great. If this is a good offer, I would like to jump on it.

I have the opprotunity to pick up a Speeco 3 point Log Splitter. Here's the description that I've been given and pictures look really good:

"I bought this on CL a few months ago for $450 and only have split a half dozen logs. I believe I am the 3rd owner, but none of us has used it very much. The splitter is designed to operate using the hydraulic system of a class 1 or 2 tractor with a 3 point hitch system. Also, you could connect it to a stand alone hydraulic pump. It works perfectly. There is some deterioration on the covering of the 8 foot hoses but they do not leak. I installed a brand new "open" type hydraulic control valve ($140) and new quick release connectors ($40). It includes legs, but I have not used them. They seem to be selling new for about $850 (which may or may not include shipping). New they usually do not include hoses and connectors (+/- $100). "

My questions are as follows:

1. Are spitters of these types worth the money?

2. I understand that they work of the hydrolics of the tractor, will there be any reason why mine will not be able to handle it?

3. I'm sure there should be more questions asked but I'm not familure enough to know which ones. Is there something else that I should be thinking of?

Here's a PIC:

Any help would be great. If this is a good offer, I would like to jump on it.