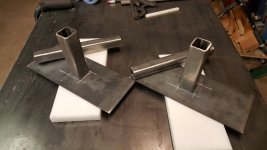

Update on my Dozer Blade UHMW skid shoes:

Well it warmed up to 20F today so working in the garage I believed I have figured out how I'm going to fabricate my new skid shoes using materials I have in my small metal rack.

By removing the 2 outer nuts for the scraper blade, the existing shoe brackets can be removed completely from the back of the Dozer Blade.

I'm going to cut a piece of square tubing 1..25" x 1.25" x 1/8" wall about 4.5" long, clean up the inside so the new square tubing 1" x 1" x 1//8" skid shoe will slip up/down when inserted.

I will weld this new 4.5" long tubing to the existing skid shoe bracket next to the existing round tube on the bracket.

Then I will cut a new piece of square tubing 1" x 1" x 1/8" wall about 9" long and weld one end to a new piece of 1/4" x 4" flat bar that's 10" long.

This new piece of flat bar will have the UHMW cut piece, 4" x 10" which will be counter sunk and fastened to the bottom of the flat bar.

This existing skid shoe spacers/washers will slip over this new square tubing and will function with the same vertical adjustments as the existing skid shoe.

By using square tubing instead of round tubing the new skid shoe will be fixed in place with no rotation of the shoe.

And by being able to use the existing spacers/washers makes all of the vertical adjustments just as easy as before.

The existing 6" diameter skid shoe has a 28 square inch surface area, and the new skid shoe has a 40 square inch surface area, which I think will make a difference.

So far this is "Plan B" and during my fabrication I just might be going to "Plan C", might increase the surface area to 6" x 12" (72 square inch surface area), or somewhere in between.

Here's a little sketch that may help others visualize my new skid shoe better:

KC

(for this project update see post #675)