grsthegreat

Super Star Member

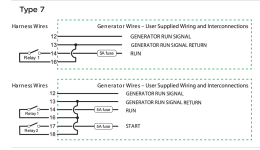

i downloaded the quick start guide, and like you say its not very specific. talks about setting generator configuration from one of 14 possible. some basic schematics. not very informative. i see a generator run signal and a generator return signal path, and various wirings depending on generator configuration you set.. it differs from each of the 14 possible combinations.

my question is....how did you figure your is version 7 ?

my question is....how did you figure your is version 7 ?