OP

CDN Farm Boy

Veteran Member

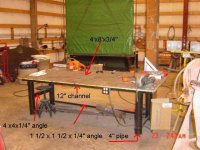

That table (from link) is overbuilt for 1/2 plate....It would work well with 2" plate or thicker. There's no need for one that much support. It would hold up a D7 dozer. The key to learning fabrication is to use materials wisely...make it strong enough, a little overbuilt maybe, but not something that heavy. You learn nothing about building by making it that way

I couldn't agree more. I'm a licensed carpenter and see this sort of over-building with wood all the time. Same with the welding, why fully weld something when some good quality and well- placed tack or stitch welds will do

I liked that one for the idea of how he did the plate and slats, scaled back on beef to a more reasonable level. Just the steak, don't need the whole cow