BMan2005

Platinum Member

- Joined

- Aug 19, 2017

- Messages

- 605

- Location

- GA

- Tractor

- 17' New Holland Workmaster 60 & 02' Kubota L3000F

Man oh man, that last picture of the weld with the cup brush beside it. You are doing great!:thumbsup::thumbsup: What a fast learner you are! :cool2::cool2::cool2:

Thanks, definitely a big learning curve on this.

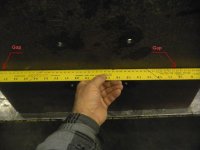

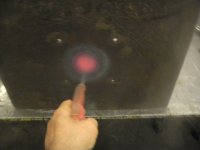

Question, when I run my 7014 over the 6011 I'm having very slight undercut on the edges of the plate. I went up & down on my amperage, tried pushing & pulling the arc, slight weave, etc... I can't seem to completely get rid of it. For the most part you can't drag your fingernail and catch the gap, but it's there and bugs me. Any recommendations?

Last edited: