BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,753

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Play with this awhile

Maximum Span Calculator for Wood Joists and Rafters

(it's also available as a phone app)

You can plug in the species that're available in your area, then enter the same variables and see the differences.

board length - if you draw out (to scale) your trusses, keeping chords so the rafter span is divided into fairly equal parts (I'm assuming the long length is for the BOTTOM chord) the drawing will suggest to you which shorter lengths should fall where your diagonal chords will fall. You can tweak the chord angles a little either way if it helps things come out better. I personally do NOT buy the exact length I need anymore, there's too much crappy wood out there to guarantee the ends will not be screwed up (knots, cracks, splits, etc) - Also, the sad state the lumber industry's in these days I ALWAYS calculate with #2, then spec #2 and BETTER (it's usually NOT much better)

If your yards will let you pick thru stacks, you might get away with actual length.

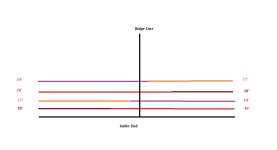

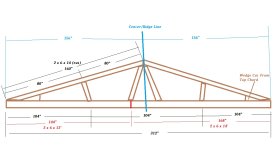

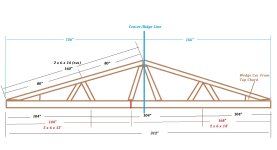

If you're spanning 26 feet and using a gable end, you're really only spanning 13 feet on each side; so if you're using (say) Douglas fir, 2x6 on 24" centers, a quick check shows 9'6" max span - if I were doing that, I'd have two diagonals per half of the roof span - they would meet the rafter in the center of its 13' span, and the bottom chord at 1/6 and 1/3 of that half's 13' span. Same on the OTHER half span (the opposite side's roof slope)

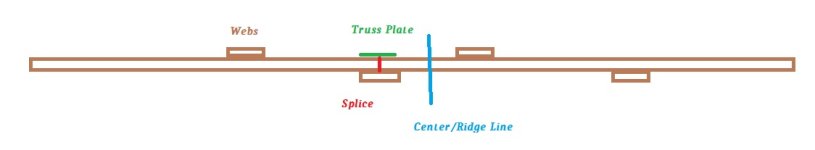

Remember, all the angled chords and the rafter (top chord) connections will be mostly in compression, and the bottom chord (splice) will be in TENSION - If you use nails, you'll want ring shanks the same length as your total thickness (for 2x material + 2 thicknesses of 1/2" ply, that'd be 2-1/2" nails ALWAYS DRIVEN SO THE NAILS WILL SELF-TIGHTEN, NOT LOOSEN.

when I built mine in place, I set them up so the two chords on either side of roof peak met in the center of span, as did the bottom chord. Those got a 2'x3' truss plate of 1/2" ply, plenty of titebond, bunches of clamps, and lots of toenailed ring shanks. That joint especially didn't get un-clamped til the glue squeeze-out started turning color (since it's the ONLY one in TENSION).

At this time, that roof has been thru 11-12 winters (on my hill, that pretty much always means several 70-80 mph storms) - it hasn't moved a bit... Steve

Maximum Span Calculator for Wood Joists and Rafters

(it's also available as a phone app)

You can plug in the species that're available in your area, then enter the same variables and see the differences.

board length - if you draw out (to scale) your trusses, keeping chords so the rafter span is divided into fairly equal parts (I'm assuming the long length is for the BOTTOM chord) the drawing will suggest to you which shorter lengths should fall where your diagonal chords will fall. You can tweak the chord angles a little either way if it helps things come out better. I personally do NOT buy the exact length I need anymore, there's too much crappy wood out there to guarantee the ends will not be screwed up (knots, cracks, splits, etc) - Also, the sad state the lumber industry's in these days I ALWAYS calculate with #2, then spec #2 and BETTER (it's usually NOT much better)

If your yards will let you pick thru stacks, you might get away with actual length.

If you're spanning 26 feet and using a gable end, you're really only spanning 13 feet on each side; so if you're using (say) Douglas fir, 2x6 on 24" centers, a quick check shows 9'6" max span - if I were doing that, I'd have two diagonals per half of the roof span - they would meet the rafter in the center of its 13' span, and the bottom chord at 1/6 and 1/3 of that half's 13' span. Same on the OTHER half span (the opposite side's roof slope)

Remember, all the angled chords and the rafter (top chord) connections will be mostly in compression, and the bottom chord (splice) will be in TENSION - If you use nails, you'll want ring shanks the same length as your total thickness (for 2x material + 2 thicknesses of 1/2" ply, that'd be 2-1/2" nails ALWAYS DRIVEN SO THE NAILS WILL SELF-TIGHTEN, NOT LOOSEN.

when I built mine in place, I set them up so the two chords on either side of roof peak met in the center of span, as did the bottom chord. Those got a 2'x3' truss plate of 1/2" ply, plenty of titebond, bunches of clamps, and lots of toenailed ring shanks. That joint especially didn't get un-clamped til the glue squeeze-out started turning color (since it's the ONLY one in TENSION).

At this time, that roof has been thru 11-12 winters (on my hill, that pretty much always means several 70-80 mph storms) - it hasn't moved a bit... Steve