Everything I am reading on the Amsoil Break in oil says it is for high performance and racing engines. There is no mention of it being ok for diesel engines. Also it is a sae 30 oil which seems awfully thick for a break in oil. The Deere Break in Plus is 10w30 and is designed for diesel engines, so I would recommend switching the oil. Leave it in for 100 hours to be sure break in is complete. If you want to change before 100 hours, I would use Break in Plus again. Deere says the break in oil is good for up to 500 hours in an engine designed for those intervals.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1969 JD 1020 diesel

- Thread starter PNW1020D

- Start date

- Views: 63310

-

- Tags

- john deere 1020

/ 1969 JD 1020 diesel

#61

That is what was scaring me after I put it in the tractor. Again from what I have read it fits all the characteristics of a proper break in oil but nothing confirmed its use for a diesel motor etc. so it was keeping me up at night lol.

I went about dropping the oil and installing a new filter. I put in JD break in plus and will run it for the first 100 hours.

From what I can see the rings have seated themselves properly, as I don't see any blow by out of the rocker cover breather tube. Is that correct in thinking?

Thanks again everyone for your knowledge.

I went about dropping the oil and installing a new filter. I put in JD break in plus and will run it for the first 100 hours.

From what I can see the rings have seated themselves properly, as I don't see any blow by out of the rocker cover breather tube. Is that correct in thinking?

Thanks again everyone for your knowledge.

Ok that makes sense.

I have ran the tractor probably 7 hours since I have completed the rebuild.

It doesn't seem to be consuming any oil.

I redid my friends driveway this weekend, so it saw some good work time of 3-4 hours. I also picked up a new attachment :thumbsup:

It was the first time I have hauled my tractor on my truck and trailer. I was a bit nervous needless to say. :laughing: The weight of a tractor on a trailer just reacts different in comparison to a mini-ex so I took it slow and steady.

And finally I have been reading up on 3pt adjustments and draft position control etc.

Here is my little lever that is under my seat.

Lets say for example I want to brush hog out in my field. Shouldn't I be in the D position?

And then lets say I want to use my ripper, shouldn't I put the lever into the LD position? And what are the other holes below the LD position?

I have ran the tractor probably 7 hours since I have completed the rebuild.

It doesn't seem to be consuming any oil.

I redid my friends driveway this weekend, so it saw some good work time of 3-4 hours. I also picked up a new attachment :thumbsup:

It was the first time I have hauled my tractor on my truck and trailer. I was a bit nervous needless to say. :laughing: The weight of a tractor on a trailer just reacts different in comparison to a mini-ex so I took it slow and steady.

And finally I have been reading up on 3pt adjustments and draft position control etc.

Here is my little lever that is under my seat.

Lets say for example I want to brush hog out in my field. Shouldn't I be in the D position?

And then lets say I want to use my ripper, shouldn't I put the lever into the LD position? And what are the other holes below the LD position?

I also have another question or concern.

So I redid my friends driveway as mentioned this past Saturday. All went well and I was simply using my rear blade and the FEL.

I loaded the tractor Saturday evening to get it back home and took it off the trailer when I got up on Sunday.

I worked around the house on Sunday, and after I finished weed whacking around the trees in the orchard, and along the fence lines, etc. I wanted to cut the grass with the brush hog.

I hooked up the brush hog and started the cut. I cut for a couple of hours, maybe a bit less.

What I noticed, that I never noticed before the rebuild, was that the exhaust pipe was vibrating, and the tractor as a whole was a bit more "rumbly" then I recall at PTO speeds.

I read this excerpt below from another tractor forum:

"Deere 300-series engine are about the easiest to work on (as used in 1020s, 2020s, 2520, etc.). The price you got sounds way high to me.

I suggest you pull the oil-pan, grab the twin balancing shafts and try to jiggle them up and down. If they are NOT loose, you can probably get by with an in-frame motor-job. If they ARE loose, the shafts are going to be ruined. I've never seen an engine that just wore the balancer bearings and not the shafts also."

So back to me....I didnt check my "twin balancing shafts":confused3:

Could this cause excessive vibration etc.?

So I redid my friends driveway as mentioned this past Saturday. All went well and I was simply using my rear blade and the FEL.

I loaded the tractor Saturday evening to get it back home and took it off the trailer when I got up on Sunday.

I worked around the house on Sunday, and after I finished weed whacking around the trees in the orchard, and along the fence lines, etc. I wanted to cut the grass with the brush hog.

I hooked up the brush hog and started the cut. I cut for a couple of hours, maybe a bit less.

What I noticed, that I never noticed before the rebuild, was that the exhaust pipe was vibrating, and the tractor as a whole was a bit more "rumbly" then I recall at PTO speeds.

I read this excerpt below from another tractor forum:

"Deere 300-series engine are about the easiest to work on (as used in 1020s, 2020s, 2520, etc.). The price you got sounds way high to me.

I suggest you pull the oil-pan, grab the twin balancing shafts and try to jiggle them up and down. If they are NOT loose, you can probably get by with an in-frame motor-job. If they ARE loose, the shafts are going to be ruined. I've never seen an engine that just wore the balancer bearings and not the shafts also."

So back to me....I didnt check my "twin balancing shafts":confused3:

Could this cause excessive vibration etc.?

Tx Jim

New Member

And finally I have been reading up on 3pt adjustments and draft position control etc.

Here is my little lever that is under my seat.

Lets say for example I want to brush hog out in my field. Shouldn't I be in the D position? [/QUOTE]

You're correct in your understanding of L/D control lever settings. "L'' is for plowing and it more sensitive sometimes ""too sensitive"" thus the use of less sensitive LD setting

And then lets say I want to use my ripper, shouldn't I put the lever into the LD position? And what are the other holes below the LD position?

Here is my little lever that is under my seat.

Lets say for example I want to brush hog out in my field. Shouldn't I be in the D position? [/QUOTE]

You're correct in your understanding of L/D control lever settings. "L'' is for plowing and it more sensitive sometimes ""too sensitive"" thus the use of less sensitive LD setting

And then lets say I want to use my ripper, shouldn't I put the lever into the LD position? And what are the other holes below the LD position?

Tx Jim

New Member

So back to me....I didnt check my "twin balancing shafts":confused3:

Could this cause excessive vibration etc.?[/QUOTE]

Only 4 cylinder engines have balancing shafts so your 1020(3 cyl) has NONE.

Could this cause excessive vibration etc.?[/QUOTE]

Only 4 cylinder engines have balancing shafts so your 1020(3 cyl) has NONE.

Wonderful.

Thanks for the information Tx. Jim.

No need to worry about the shafts for me then lol.

I was reading up on my tractors powering steering and I came upon an old comment you left about another member's 1020.

"FYI early 1020's had a powersteering pump mounted to frt of engine so be sure oil level rise isn't hyd oil instead of diesel"

So, since my engine block was the early style, I would think I also have this early style power steering pump?

What does it look like? And where exactly is it mounted etc?

Thanks everyone!!!

Thanks for the information Tx. Jim.

No need to worry about the shafts for me then lol.

I was reading up on my tractors powering steering and I came upon an old comment you left about another member's 1020.

"FYI early 1020's had a powersteering pump mounted to frt of engine so be sure oil level rise isn't hyd oil instead of diesel"

So, since my engine block was the early style, I would think I also have this early style power steering pump?

What does it look like? And where exactly is it mounted etc?

Thanks everyone!!!

Tx Jim

New Member

Ok thank you Tx. Jim.

That range of serial numbers is prior to mine, so that must mean I have an internally mounted power steering pump?

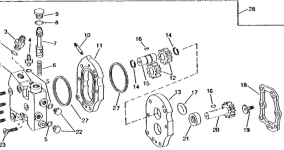

Please see the attached photo.

Is this my main hydraulic pump then? It seems to be "whining" to my ears. :confused3:

Also, here is a pic of a new tool I just got assembled last weekend. With working on my f-350 dually, as well as the 1020, it really is wonderful to have this overhead creeper. I recommend it, even though I initially thought I would never use it, I really do utilize it.

That range of serial numbers is prior to mine, so that must mean I have an internally mounted power steering pump?

Please see the attached photo.

Is this my main hydraulic pump then? It seems to be "whining" to my ears. :confused3:

Also, here is a pic of a new tool I just got assembled last weekend. With working on my f-350 dually, as well as the 1020, it really is wonderful to have this overhead creeper. I recommend it, even though I initially thought I would never use it, I really do utilize it.