GuglioLS

Veteran Member

- Joined

- Feb 13, 2005

- Messages

- 1,155

- Location

- Edgewood, NM USA

- Tractor

- Jinma 354, 1953 Ford NAA Golden Jubilee, Komatsu Bulldozer

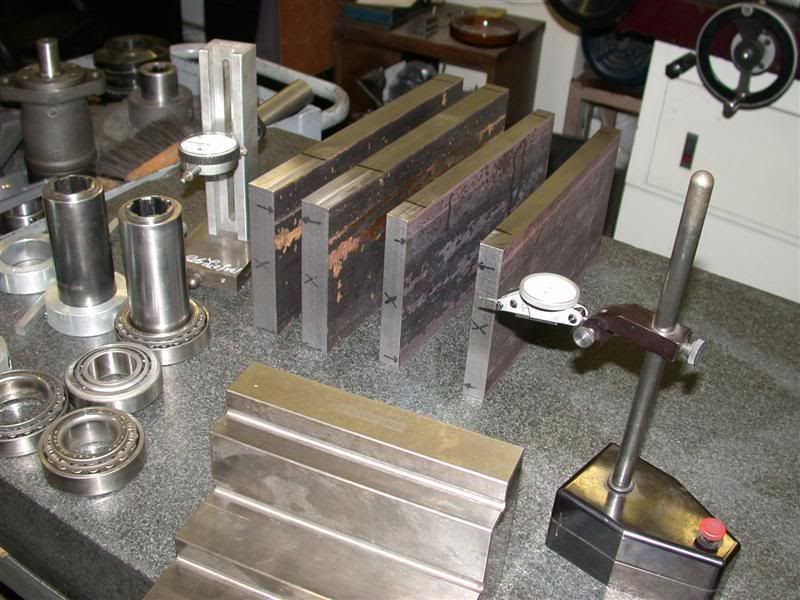

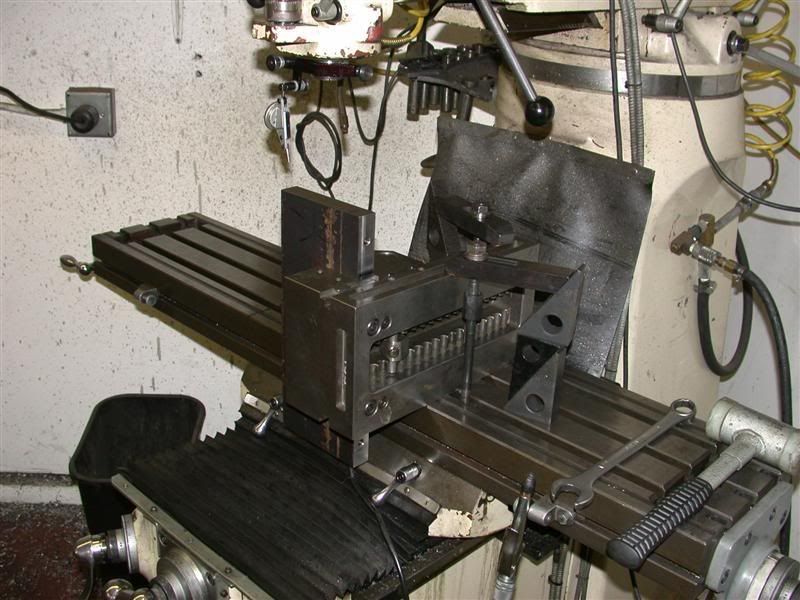

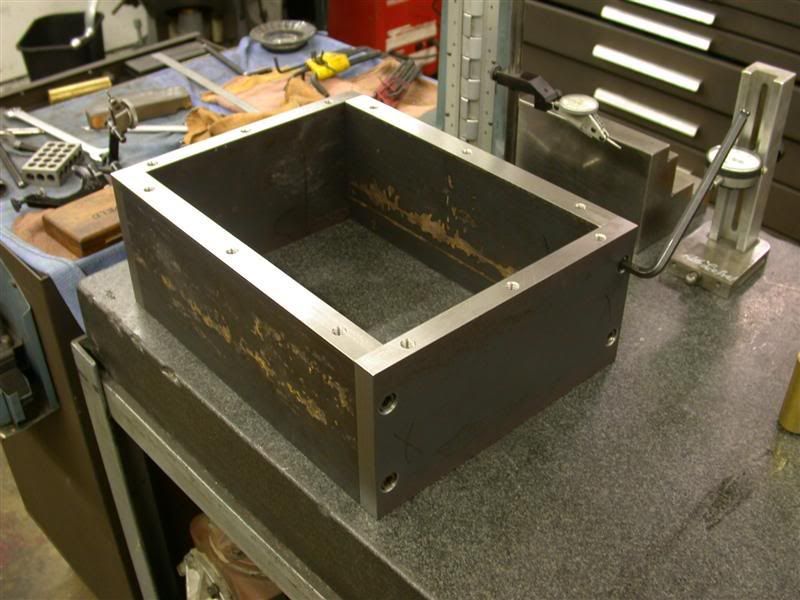

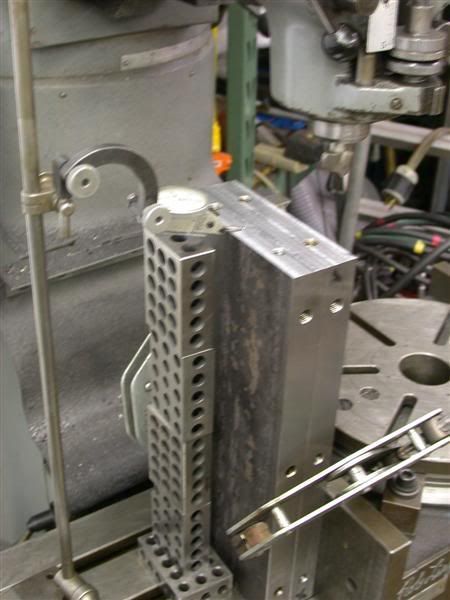

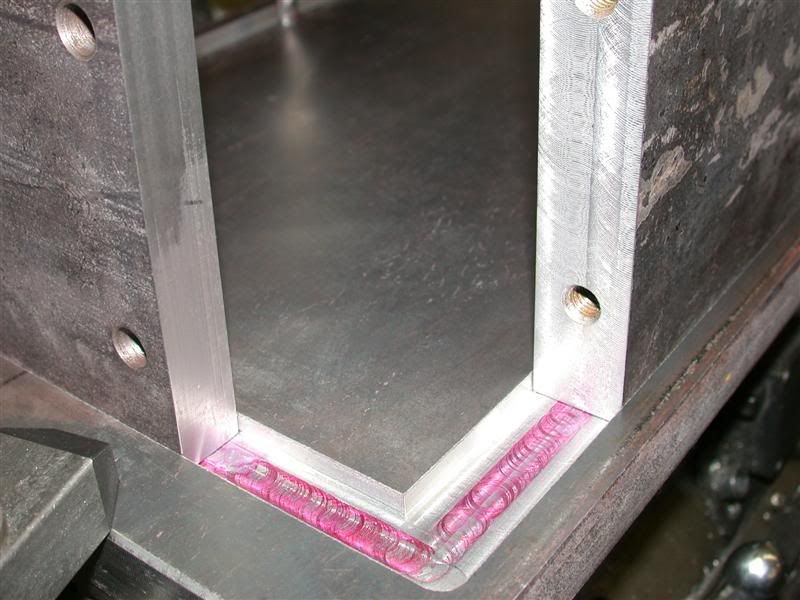

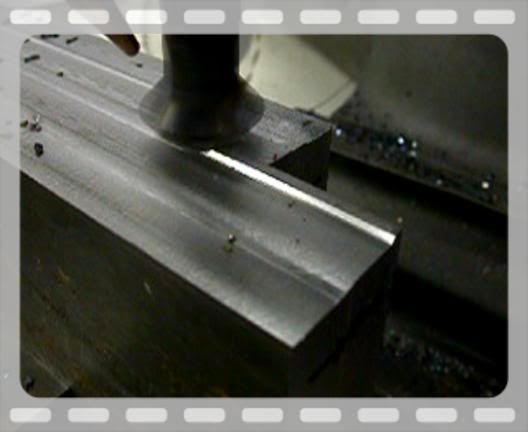

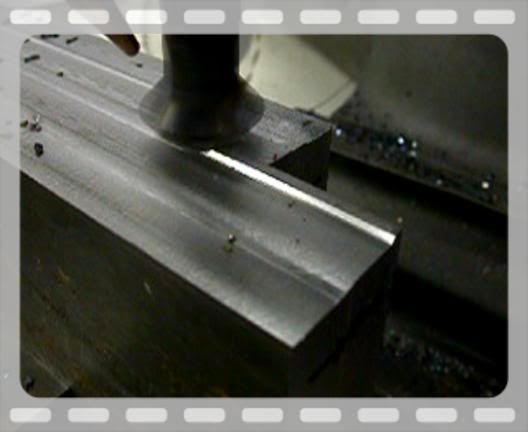

There is a lot of prep work to make sure the plates are square and parallel for when I do my hole bores. I'll know they will line up and not be cockeyed to each other causing binding or something.

Here's a short video of one pass. Sorry it's not that great but I had to dodge hot chips while filming. It only shows the last strip being cut left on the longer plates though.

I was machining .080" a pass at 20" a minute (approx) with air cooling the inserted carbide mill cutter. I machined all the plates together because they all had to end up the same size.

Rob-

Here's a short video of one pass. Sorry it's not that great but I had to dodge hot chips while filming. It only shows the last strip being cut left on the longer plates though.

I was machining .080" a pass at 20" a minute (approx) with air cooling the inserted carbide mill cutter. I machined all the plates together because they all had to end up the same size.

Rob-