You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3800 Pound South Bend 17" Turn-Nado Lathe Project

- Thread starter PineRidge

- Start date

- Views: 24791

/ 3800 Pound South Bend 17" Turn-Nado Lathe Project

#31

Brad_Blazer

Veteran Member

PineRidge

Super Member

PineRidge

Super Member

Re: 3800 Pound South Bend 17\" Turn-Nado Lathe Project

The headstock has now been placed on the main bed for final preparation before reassembly. There's a brake/clutch shaft that exits the headstock directly from the bottom of the casting and that piece will need to be installed before the headstock can be slid into its final position.

The headstock has now been placed on the main bed for final preparation before reassembly. There's a brake/clutch shaft that exits the headstock directly from the bottom of the casting and that piece will need to be installed before the headstock can be slid into its final position.

Attachments

PineRidge

Super Member

Re: 3800 Pound South Bend 17\" Turn-Nado Lathe Project

The 5 HP 3 phase powerplant has been, cleaned, inspected, painted and is now ready to be reinstalled. We have decided to power it up on 3 phase using a VFD (variable frequency drive).

VFD Operation

When a VFD starts a motor, it initially applies a low frequency and voltage to the motor. The starting frequency is typically 2 Hz or less. Starting at such a low frequency avoids the high inrush current that occurs when a motor is started by simply applying the utility (mains) voltage by turning on a switch. When a VFD starts, the applied frequency and voltage are increased at a controlled rate or ramped up to accelerate the load without drawing excessive current. This starting method typically allows a motor to develop 150% of its rated torque while drawing only 150% of its rated current. When a motor is simply switched on at full voltage, it initially draws at least 300% of its rated current while producing less than 150% of its rated torque. As the load accelerates, the available torque usually drops a little and then rises to a peak while the current remains very high until the motor approaches full speed. A VFD can be adjusted to produce a steady 150% starting torque from standstill right up to full speed while drawing only 150% current.

With a VFD, the stopping sequence is just the opposite as the starting sequence. The frequency and voltage applied to the motor are ramped down at a controlled rate. When the frequency approaches zero, the motor is shut off. A small amount of braking torque is available to help decelerate the load a little faster than it would stop if the motor were simply switched off and allowed to coast. Additional braking torque can be obtained by adding a braking circuit to dissipate the braking energy or return it to the power source.

The 5 HP 3 phase powerplant has been, cleaned, inspected, painted and is now ready to be reinstalled. We have decided to power it up on 3 phase using a VFD (variable frequency drive).

VFD Operation

When a VFD starts a motor, it initially applies a low frequency and voltage to the motor. The starting frequency is typically 2 Hz or less. Starting at such a low frequency avoids the high inrush current that occurs when a motor is started by simply applying the utility (mains) voltage by turning on a switch. When a VFD starts, the applied frequency and voltage are increased at a controlled rate or ramped up to accelerate the load without drawing excessive current. This starting method typically allows a motor to develop 150% of its rated torque while drawing only 150% of its rated current. When a motor is simply switched on at full voltage, it initially draws at least 300% of its rated current while producing less than 150% of its rated torque. As the load accelerates, the available torque usually drops a little and then rises to a peak while the current remains very high until the motor approaches full speed. A VFD can be adjusted to produce a steady 150% starting torque from standstill right up to full speed while drawing only 150% current.

With a VFD, the stopping sequence is just the opposite as the starting sequence. The frequency and voltage applied to the motor are ramped down at a controlled rate. When the frequency approaches zero, the motor is shut off. A small amount of braking torque is available to help decelerate the load a little faster than it would stop if the motor were simply switched off and allowed to coast. Additional braking torque can be obtained by adding a braking circuit to dissipate the braking energy or return it to the power source.

Attachments

Jagmandave

Veteran Member

Re: 3800 Pound South Bend 17\" Turn-Nado Lathe Project

Won't you need a 3 ph power source too?

Variable freq drives are a great way to control a motor, you can set the speed extremely accurately with one, not to mention the soft start and stop features. Good choice, prices have come down significantly over the last 5 years too. What brand VFD are you using? I use AB's a lot in my plant.......

Won't you need a 3 ph power source too?

Variable freq drives are a great way to control a motor, you can set the speed extremely accurately with one, not to mention the soft start and stop features. Good choice, prices have come down significantly over the last 5 years too. What brand VFD are you using? I use AB's a lot in my plant.......

PineRidge

Super Member

Re: 3800 Pound South Bend 17\" Turn-Nado Lathe Project

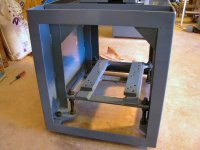

Well the headstock has now been reattached to the lathe bed. I cleaned up all the surfaces where the various gaskets and bearings will meet the metal and it's time for reassembly of the headstock assembly.

This is the clutch/brake assembly that transfers the energy from the 5 HP 3 phase motor to the gearbox via the single gear shown (lower right). This assembly uses multiple disc's much the same way as an automatic transmission in a automobile however in this application the clutch/brake mechanism is operated manually. The smaller shaft extension on the right side drives the main oil pump that keeps all the gears within the headstock well lubricated while in operation.

This assembly along with the associated linkage will be the first fitted into the headstock.

Well the headstock has now been reattached to the lathe bed. I cleaned up all the surfaces where the various gaskets and bearings will meet the metal and it's time for reassembly of the headstock assembly.

This is the clutch/brake assembly that transfers the energy from the 5 HP 3 phase motor to the gearbox via the single gear shown (lower right). This assembly uses multiple disc's much the same way as an automatic transmission in a automobile however in this application the clutch/brake mechanism is operated manually. The smaller shaft extension on the right side drives the main oil pump that keeps all the gears within the headstock well lubricated while in operation.

This assembly along with the associated linkage will be the first fitted into the headstock.

Attachments

scott_vt

Super Member

- Joined

- Oct 5, 2004

- Messages

- 7,437

- Location

- east wells,vt

- Tractor

- 1986 MF 1040, 1942 Farmall A, 1949 Farmall Super A

Re: 3800 Pound South Bend 17\" Turn-Nado Lathe Project

</font><font color="blue" class="small">( The smaller shaft extension on the right side drives the main oil pump that keeps all the gears within the headstock well lubricated while in operation )</font>

Mornin Mike,

Providing that you can see your oil level through the site window on the gearbox /forums/images/graemlins/grin.gif

All kidding aside, looks like youve got everything under control, white towels and all /forums/images/graemlins/grin.gif

scotty

</font><font color="blue" class="small">( The smaller shaft extension on the right side drives the main oil pump that keeps all the gears within the headstock well lubricated while in operation )</font>

Mornin Mike,

Providing that you can see your oil level through the site window on the gearbox /forums/images/graemlins/grin.gif

All kidding aside, looks like youve got everything under control, white towels and all /forums/images/graemlins/grin.gif

scotty

Jagmandave

Veteran Member

Re: 3800 Pound South Bend 17\" Turn-Nado Lathe Project

Cool, I did not know you could use single phase input, all the ones I have in my plant are 3 ph in and out. This is what I use, i think it's rated for up to 5 hp also, about $500 brand new from Allen Bradly. The pic might be deceiving, it's only about 6" tall X 3" wide.

Cool, I did not know you could use single phase input, all the ones I have in my plant are 3 ph in and out. This is what I use, i think it's rated for up to 5 hp also, about $500 brand new from Allen Bradly. The pic might be deceiving, it's only about 6" tall X 3" wide.