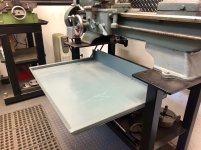

Getting it set up is going to take a while but do have 120 volts where it is stored so we can spin it up. Here is a shoot from yesterday with the machines awaiting our pick up day arrival. We are going to repaint the mill and now better understand the bondo remark.

View attachment 602475

View attachment 602475

I see this is the rear view of both the 6 and 12 inch lathes so I will add front views. Keep in mind the 6" may appear larger because it is shorter and framed on the length. Both came with collets, 3 jaw and 4 jaw chucks I know but have yet to inventory boxes of parts. The 6" one does also come with follow rest and a steady rest, two milling attachments for sure. The 12" lathe comes with quick gear change attachment and all of the parts including the gear cover lid to take it back stock. The stock tool post is in a parts box since it has a newer 4 post tool holder currently installed.

There are some MT drill bits, dead and live centers and tons of HS and carbide cutting tools, etc but I think the set of boring tools are HS steel only. In time I will sort through these. Getting the house gutted and back together by September is job one then we can start on fixing a machine shop area in the shop building. Thankfully we have power in the storage place so I can check out the lathes, lube, adjust, ect currently making sure the fresh concrete keeps looking that way.

6" Craftsman lathe. I have an invoice for $650 dated 1983 from a machine tool company so perhaps it was bought used since I think that was past the Sears marketing of this lathe. The story is the guy just wanted to train himself on metal working. He was also the owner of the 12" lathe but I have no paper purchase history on it. Based on the stack of books that came with the lathes I expect the self training story is factual.

12" Craftsman Lathe

So far I see no signs either have been repainted or even touched up so little to no use beyond hobby use could be factual. The other machines can be blown up in the group picture I think. The grinder/buffer and belt sander are not old equipment but the powered hacksaw and 2 drill presses are old. You can see the old Craftsman tool theme was underway. Perhaps the theme may continue.

By the way I am looking for a manual and parts diagrams for the Select brand milling machine that started this ball rolling since it is the Odd Man Out imported machine. It should look like new when cleaned, painted and lubed well as we go back together with the mill.