RonMar said:

Ok Cliff

So how exactly is the new burner configured? I see fuel, and I am assuming air from the blower going into the top, bright orange case and flame comming out the back... I see the part you were calling the funnel on the end of the downpipe. Dosn't that restrict airflow? Or does it instead focus/increase it's velocity along with starting to atomize the fuel?

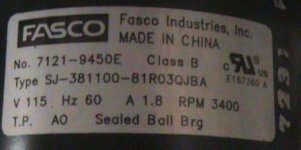

That is one heck of a sturdy looking stove

The blower motor is several feet away from the stove, reason being, I wanted cooler air entering the stove (keeps the funnel from over heating and cooking the oil in the oil line). The pipe that the blower motor is connected to is 2 3/4 inch. I had the velocity but not enough pressure to atomize the oil. The more and more test I tried. I finally realized I wanted more (atomizing the oil). Plus my burner before this gave me a back draft which in return gave me first and second degree burns on my face. That setup worked rather well. But the conditions were favorable that day and my timing was rather stupid and the end result, I got a face full of fire. So, I decided the time was to re-think this setup and move to the next level and see how my idea of using a funnel would bring. This was a rather time consuming and unplanned idea. But I jumped right in and started looking for a steel funnel that could handle some heat. I looked high and low and was about to give up and just build one out of sheet metal and go from there. I was at tractor supply one day and it occurred to me that a cap off a welding or torch bottle would work. So, I bought one and got home and cut the top off it. Drilled a hole on each side and welded a nut over the hole. The opening for the oil ended up, having to be a 1 inch hole. Tried other smaller sizes, but they restricted the air. Finnally got to 1 inch and decide this was good. So, I set it up and gave it a try on my old setup burner, skillet, conical and the piece of flue pipe. After several test, I realized the flue pipe needed to higher than the conical so that the flame would flow underneith the flue pipe. My one video (waste oil burning stove) on you tube shows this setup. But my problem with that setup was, the flame would flow underneith the flue pipe and some of the flame would stay in the middle and come back up toward the funnel and one test I was doing, the funnel was glowing red hot. As soon as I seen this, I turned the oil off cause the heat was traveling up the pipe toward the oil line and it sounded like popcorn was inside the air pipe. My oil line is only about 3 inches from the end of the air pipe. Then it occured to me that if I compress the flame inside of some tube, the flame could not get to the funnel and anything up higher like the oil line. While I stood there letting the blower motor cool the funnel down. I walked around my shop over to my pile of metal and dug out a piece of pipe. This pipe is 20 inchs long and the inside is, if I remember right, its 6 1/2 inchs and its 3/8 inch thick. Then I found another piece of pipe that was 3 inchs long. I cut a hole in the tube and welded this pipe inside of the hole. I used this pipe cause it 1/2 inch thick. I thought that since its thick, it will take longer to heat up. I was right, you can see the tube is cherry red and the short pipe that the oil passes into is not. Video 3 shows this. Since the metal is thicker and the air is compressed, this pipe can not turn cherry red. It gets hot, but the heat can not travel to the funnel and the oil line. I also decide to weld some hinges from things I had around my shop and also make a door. I decided kerosene was going to be the starter fuel

no more ($4.00 a gallon here). I decide I was going to use shredded paper (all paper of value gets shredded) and I have several bags that need burned. So, I built the door. Fill with shredded paper, lite paper and close door and turn on oil (very little) and after about 2 minutes, turn the blower motor to full power. While the paper and small amount of oil is burning, I have the blower motor turned on a low setting. This helps it to get hot faster. Two minutes later, blower full power. I have a draggon inside the tube. 8 minutes later, is when I made video 3 and 4. Video 4, I could not even open the door cause of how much heat was inside. The top heat exchanger barrel on the stove was hitting 450 degrees.

Also, the funnel does restrict the air some cause the blower motor now runs cooler. These blowers need some back pressure, cause thats how they cool themselfs.

Later on, I will be cutting the funnel some more, so that the outer edge is the same size as the down air pipe. But just a little bit bigger so that I can weld a piece of pipe on it. That will allow me to slip the funnel over the down air pipe. And at a later date, I can slip the funnel off and check the oil line. If it needs probed with a gun barrel brush, I can clean it. When I'm done, slip the funnel back on.

~ ~

~ ~ ~ ~

~ ~ ~

~ "\

"\ /"

/"