You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Caterpillar Diverter Valve

- Thread starter bindian

- Start date

- Views: 32459

More options

Who Replied?

/ Caterpillar Diverter Valve

#41

bindian

Super Member

Does anyone know where I can get 3/4 inch ID tubing? I need two pieces 11 feet long for hard lines going over the boom. I will form it and bend the one end at 45 degrees. They have my local welding shop weld these JIC fittings on the ends...... 6400-08-08 | 1/2" JIC Male x #8 SAE/ORB Male

hugs, Brandi

hugs, Brandi

kennyd

Advertiser

Brandi,

The same place you bought the diverter from sells it

Product Index | Trausch Dynamics[catalog]=1&data[parent]=400001

The same place you bought the diverter from sells it

Product Index | Trausch Dynamics[catalog]=1&data[parent]=400001

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Got me curious when referring to tubing as ID - Kenny your link lists tubing OD (as I'm used to seeing for tubing), plus a minimum order of 200 feet -

Product Index | Trausch Dynamics[catalog]=1&data[grp_id]=4601

Brandi, any special reason you want that large a tubes only to neck down to a -8 (half inch) fitting?

I've bought half and 3/4" OD tubing from my semi-local steel supplier, it came in 20 foot lengths and they had to special order it.

For what you want, you might need to ask for a 24' length (if they're available) or you'd end up with a couple 9' leftovers. Guessing that's STILL cheaper than buying 200 feet though

Knowing your aircraft background, I'm sure you already know about wall thickness vs. pressure - I'm guessing this is for your new thumb?

Sorry, don't mean to have more questions than answers... Steve

Second sorry - their site isn't very friendly, I linked the page I was on and it comes back to the main page - I went to Hydraulics/tubing to get there...

Product Index | Trausch Dynamics[catalog]=1&data[grp_id]=4601

Brandi, any special reason you want that large a tubes only to neck down to a -8 (half inch) fitting?

I've bought half and 3/4" OD tubing from my semi-local steel supplier, it came in 20 foot lengths and they had to special order it.

For what you want, you might need to ask for a 24' length (if they're available) or you'd end up with a couple 9' leftovers. Guessing that's STILL cheaper than buying 200 feet though

Knowing your aircraft background, I'm sure you already know about wall thickness vs. pressure - I'm guessing this is for your new thumb?

Sorry, don't mean to have more questions than answers... Steve

Second sorry - their site isn't very friendly, I linked the page I was on and it comes back to the main page - I went to Hydraulics/tubing to get there...

bindian

Super Member

I reasoned I could use the JIC/SAE -8 fittings I had and just stick the SAE end into the tubing and weld a bead around it at the hex flats. I really could use smaller ID, if I needed. 3/4 just seemed easier to weld since it would fit in the tube, if I ground the threads down a little.

I have sent out for some quotes and their lengths are around 24 feet. Hopefully I can talk to the owner of my local welding shop today for supplier infor.

I gather around .060 to .080 wall thickness will be right, depending on what material it is. My CAT system is just 2450 psi.

hugs, Brandi

I have sent out for some quotes and their lengths are around 24 feet. Hopefully I can talk to the owner of my local welding shop today for supplier infor.

I gather around .060 to .080 wall thickness will be right, depending on what material it is. My CAT system is just 2450 psi.

hugs, Brandi

bindian

Super Member

I posted here yesterday, but it didn't come up. I'll call them today.Brandi,

The same place you bought the diverter from sells it

Product Index | Trausch Dynamics[catalog]=1&data[parent]=400001

hugs, Brandi

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

"I gather around .060 to .080 wall thickness will be right, depending on what material it is. My CAT system is just 2450 psi."

Yeah, but you may wanna consider staying with 1/2" - 3/4" is half again the cost, needs a thicker wall for same pressure. 1/2" OD should be at least .065" wall, where 3/4" would need to be .083" - plus DHH carries a "swagelok" type fitting that will let you crimp JIC's straight onto hard tubing - you'd need a nut

Convert-A-Flare Tube Nut

A sleeve

Discount Hydraulic Hose

and a JIC fitting (male) - I clamp the fitting in a vise for assembly, but it can also be done in the field. If you've ever used Swagelok tube fittings you can do these. If you decide to go this way, I have a chart showing # of turns for each size I can post. These are strong enough your tubing will split before the fitting gives up... Steve

Yeah, but you may wanna consider staying with 1/2" - 3/4" is half again the cost, needs a thicker wall for same pressure. 1/2" OD should be at least .065" wall, where 3/4" would need to be .083" - plus DHH carries a "swagelok" type fitting that will let you crimp JIC's straight onto hard tubing - you'd need a nut

Convert-A-Flare Tube Nut

A sleeve

Discount Hydraulic Hose

and a JIC fitting (male) - I clamp the fitting in a vise for assembly, but it can also be done in the field. If you've ever used Swagelok tube fittings you can do these. If you decide to go this way, I have a chart showing # of turns for each size I can post. These are strong enough your tubing will split before the fitting gives up... Steve

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Found a couple pix of the flareless JIC's on my 580 (part of a larger project incl. loader QA, grapple, etc) - these are 3/8", don't need speed for anything these extra remotes will control - sorry about the "bundle of snakes", I wanted to keep these as low to the deck as possible

Attachments

bindian

Super Member

"I gather around .060 to .080 wall thickness will be right, depending on what material it is. My CAT system is just 2450 psi."

Yeah, but you may wanna consider staying with 1/2" - 3/4" is half again the cost, needs a thicker wall for same pressure. 1/2" OD should be at least .065" wall, where 3/4" would need to be .083" - plus DHH carries a "swagelok" type fitting that will let you crimp JIC's straight onto hard tubing - you'd need a nut

Convert-A-Flare Tube Nut

A sleeve

Discount Hydraulic Hose

and a JIC fitting (male) - I clamp the fitting in a vise for assembly, but it can also be done in the field. If you've ever used Swagelok tube fittings you can do these. If you decide to go this way, I have a chart showing # of turns for each size I can post. These are strong enough your tubing will split before the fitting gives up... Steve

We just started using Swagelok fittings, for repairs, at the hangar. So far, no one on our crew has did the procedure. I sent you a PM. My mind is on welded fittings, but I am open to the JIC convert a flare

hugs, Brandi

bindian

Super Member

Found a couple pix of the flareless JIC's on my 580 (part of a larger project incl. loader QA, grapple, etc) - these are 3/8", don't need speed for anything these extra remotes will control - sorry about the "bundle of snakes", I wanted to keep these as low to the deck as possible

I like your installation with hard lines at the valves. What do the two valves do? Are those lines stainless?

Just price 1/2 inch JIC flareless connectors...........at $23.86 each!

27208-08-08 | 1/2" JIC Male x 1/2" Flareless

But the cost of the items seperate, the way you did it, is total....$$5.26. What is the difference? Or am I missing something?

hugs, Brandi

Last edited:

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

"I like your installation with hard lines at the valves. What do the two valves do? Are those lines stainless?"

Right now, the 2 valves don't do ANYTHING - when the dust settles (eventually) they will control whatever extras I have mounted on the FEL - when the grapple is on, one of them will control that - when the hydraulic sickle bar is on, I already have a flow control for that but the two solenoids will control articulation cylinders on 2 separate joints to change reach and angle - both will be inserted in the bucket curl circuit so I'll have the choice of either curl, articulation 1 or 2.

Yeah, the hard lines are stainless, but those and the mounting plate will need to be re-done, since some dummy mounted the solenoid valves BACKWARD - trying to keep the solenoids and electrical protected. When it's finished the solenoids will need to be on the opposite end, and I'll fab a shield from 1/4" plate as well as a reversed mounting bracket (duh....)

- trying to keep the solenoids and electrical protected. When it's finished the solenoids will need to be on the opposite end, and I'll fab a shield from 1/4" plate as well as a reversed mounting bracket (duh....)

"Just price 1/2 inch JIC flareless connectors...........at $23.86 each!

27208-08-08 | 1/2" JIC Male x 1/2" Flareless

But the cost of the items seperate, the way you did it, is total....$$5.26. What is the difference? Or am I missing something?"

Yes - for some reason, male JIC's often cost more than females - your link is for a MALE JIC end, and the individual pieces I linked are just the female JIC sleeve with a female nut - they're installed by gently screwing the nut onto a male JIC fitting (with the sleeve INSIDE the nut), then inserting the tubing into both and finally tightening the nut onto the male JIC fitting til the sleeve is crimped onto the tube. IMO, the ones you linked are grossly overpriced so I've used the separate components to make a female JIC, then if you need that end to be MALE, just get a male/male JIC and screw THAT into the tube-mounted female.

In 1/2" size, that male/male JIC adds a whole $1.07, for a whopping total of $6.33 instead of $23.86...

JIC 37° Tube Union (Steel)

If you're just getting into Swage-lok stuff at work, they have VERY specific tightening instructions that vary somewhat with the size - the reason for that is removability - if you don't tighten the fitting ENOUGH, it will leak. IF you tighten it to spec, if won't leak and you can unscrew it and put it back together easily with no leaks.

If you tighten it TOO much, you will upset the end of the tubing that seats inside the fitting too much, swelling it so it won't come out. If you tighten it THREE much it's possible to get a stress crack in the fitting body.

it's possible to get a stress crack in the fitting body.

These flareless fittings are NOT Swage-lok, but work similarly - with both, you want them tightened just til you can see a SLIGHT deformation where the sleeve fits around the tubing - less, and they'll come apart under pressure; too much, and they can deform and leak.

When I first started using the flareless fittings, I bought a few spares so I could screw up a couple as a learning experience - I found you can get it figured out in 2-3 tries by just paying attention, knowing approximately how much to tighten, and looking at where the crimped sleeve joins the tubing.

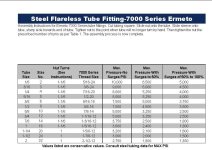

Here's a different brand's chart that worked fine for me... Steve

Right now, the 2 valves don't do ANYTHING - when the dust settles (eventually) they will control whatever extras I have mounted on the FEL - when the grapple is on, one of them will control that - when the hydraulic sickle bar is on, I already have a flow control for that but the two solenoids will control articulation cylinders on 2 separate joints to change reach and angle - both will be inserted in the bucket curl circuit so I'll have the choice of either curl, articulation 1 or 2.

Yeah, the hard lines are stainless, but those and the mounting plate will need to be re-done, since some dummy mounted the solenoid valves BACKWARD

"Just price 1/2 inch JIC flareless connectors...........at $23.86 each!

27208-08-08 | 1/2" JIC Male x 1/2" Flareless

But the cost of the items seperate, the way you did it, is total....$$5.26. What is the difference? Or am I missing something?"

Yes - for some reason, male JIC's often cost more than females - your link is for a MALE JIC end, and the individual pieces I linked are just the female JIC sleeve with a female nut - they're installed by gently screwing the nut onto a male JIC fitting (with the sleeve INSIDE the nut), then inserting the tubing into both and finally tightening the nut onto the male JIC fitting til the sleeve is crimped onto the tube. IMO, the ones you linked are grossly overpriced so I've used the separate components to make a female JIC, then if you need that end to be MALE, just get a male/male JIC and screw THAT into the tube-mounted female.

In 1/2" size, that male/male JIC adds a whole $1.07, for a whopping total of $6.33 instead of $23.86...

JIC 37° Tube Union (Steel)

If you're just getting into Swage-lok stuff at work, they have VERY specific tightening instructions that vary somewhat with the size - the reason for that is removability - if you don't tighten the fitting ENOUGH, it will leak. IF you tighten it to spec, if won't leak and you can unscrew it and put it back together easily with no leaks.

If you tighten it TOO much, you will upset the end of the tubing that seats inside the fitting too much, swelling it so it won't come out. If you tighten it THREE much

These flareless fittings are NOT Swage-lok, but work similarly - with both, you want them tightened just til you can see a SLIGHT deformation where the sleeve fits around the tubing - less, and they'll come apart under pressure; too much, and they can deform and leak.

When I first started using the flareless fittings, I bought a few spares so I could screw up a couple as a learning experience - I found you can get it figured out in 2-3 tries by just paying attention, knowing approximately how much to tighten, and looking at where the crimped sleeve joins the tubing.

Here's a different brand's chart that worked fine for me... Steve

Attachments

bindian

Super Member

I was in Alvin, Texas today at Tubing & Metric Hydraulics. I love this place because it is just 18 miles from work. I bought two 12 foot lengths of 1/2 inch .065 wall tubing and 4 tube end adapter fittings FL-2000-08-08. The tubing was $4.67 a foot and the "compression" adapter fittings were $11.84 each.

hugs, Brandi

hugs, Brandi

bindian

Super Member

If you tighten it TOO much, you will upset the end of the tubing that seats inside the fitting too much, swelling it so it won't come out. If you tighten it THREE muchit's possible to get a stress crack in the fitting body.

Stress cracks.........reminds me of making AN (JIC) stainless steel flares on lines for DC-9s. Tighten the flaring tool too tight and oops, crack.........start over

Thanks for the instructions.

hugs, Brandi

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Brandi, good talking to you tonite - I hope BOTH of us can get life to smile at us a bit more soon

Just in case you (or others who read this) don't already know, these compression type fittings are NOT like torqueing a bolt - by that, I mean that ALL bolts have a recommended torque spec (except the ones that actually measure STRETCH on the bolt to achieve the required amount of "crush") - but torque specs are DIFFERENT for the same bolt depending on whether it's dry or lubed, and even slightly different depending on what KIND of lube is used -

This is NOT true of compression fittings, which normally use the # of TURNS past a certain point (like when the tube won't move by hand) - dry OR lubed, if they call for 6-1/6 turns (AKA "7 FLATS") then that's what they mean. That # of turns will ALWAYS compress the "guts" of the connector the same amount, whether dry or lubed; so I always use lube (just on the threads, though) so there's less chance of galling on the threads.

Hope this helps... Steve

Just in case you (or others who read this) don't already know, these compression type fittings are NOT like torqueing a bolt - by that, I mean that ALL bolts have a recommended torque spec (except the ones that actually measure STRETCH on the bolt to achieve the required amount of "crush") - but torque specs are DIFFERENT for the same bolt depending on whether it's dry or lubed, and even slightly different depending on what KIND of lube is used -

This is NOT true of compression fittings, which normally use the # of TURNS past a certain point (like when the tube won't move by hand) - dry OR lubed, if they call for 6-1/6 turns (AKA "7 FLATS") then that's what they mean. That # of turns will ALWAYS compress the "guts" of the connector the same amount, whether dry or lubed; so I always use lube (just on the threads, though) so there's less chance of galling on the threads.

Hope this helps... Steve

bindian

Super Member

Steve,Brandi, good talking to you tonite - I hope BOTH of us can get life to smile at us a bit more soon

Just in case you (or others who read this) don't already know, these compression type fittings are NOT like torqueing a bolt - by that, I mean that ALL bolts have a recommended torque spec (except the ones that actually measure STRETCH on the bolt to achieve the required amount of "crush") - but torque specs are DIFFERENT for the same bolt depending on whether it's dry or lubed, and even slightly different depending on what KIND of lube is used -

This is NOT true of compression fittings, which normally use the # of TURNS past a certain point (like when the tube won't move by hand) - dry OR lubed, if they call for 6-1/6 turns (AKA "7 FLATS") then that's what they mean. That # of turns will ALWAYS compress the "guts" of the connector the same amount, whether dry or lubed; so I always use lube (just on the threads, though) so there's less chance of galling on the threads.

Hope this helps... Steve

What do you lube the threads with?

hugs, Brandi

bindian

Super Member

The air intake hose came in today. Here it is with the air filter assembly raised 2 inches.

Also the hoses from Discount Hydraulic Hose came in. Here is the relief filter to tank line installed.

hugs, Brandi

Also the hoses from Discount Hydraulic Hose came in. Here is the relief filter to tank line installed.

hugs, Brandi

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Lookin' good Brandi, I like your work -

"What do you lube the threads with?"

sometimes if it's a fitting I'm likely to rub up against, I'll just use a little Tri-Flow (not as obvious on your shirt ) - otherwise it's a light coating of Never-Seize, I find the fittings don't argue so much when you need to take 'em apart after a few heat/cool cycles... Steve

) - otherwise it's a light coating of Never-Seize, I find the fittings don't argue so much when you need to take 'em apart after a few heat/cool cycles... Steve

"What do you lube the threads with?"

sometimes if it's a fitting I'm likely to rub up against, I'll just use a little Tri-Flow (not as obvious on your shirt

bindian

Super Member

Lookin' good Brandi, I like your work -

"What do you lube the threads with?"

sometimes if it's a fitting I'm likely to rub up against, I'll just use a little Tri-Flow (not as obvious on your shirt) - otherwise it's a light coating of Never-Seize, I find the fittings don't argue so much when you need to take 'em apart after a few heat/cool cycles... Steve

This is what we used on piston powered airplane spark plug threads. LOCTITE C5-A Copper Anti-Seize - Loctite

A little dab would do you.

hugs, Brandi

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Yeah, I might even still have some of that around - we used it on 50,000 amp water-cooled buss bars for vacuum arc melt furnaces - every thing on those was copper, right down to nuts/bolts/washers/lock washers that bolted the sections together - the "never-seize" I referred to earlier is actually Chesterton's high nickel anti-seize, good for both steel and stainless steel fasteners - been using the same can for maybe 10 years now, good thing it doesn't go bad if you keep the lid on tight :laughing: ... Steve

bindian

Super Member

I wanted to give my local hydraulic shop some business during this installation project. So I let them build two 3/4 inch hoses with BSPP fittings. I got up early Monday to do this. I told them I needed two 24 inch lines. He handed them to me (made while I waited) and I paid for them, while my mind was screaming....................they look short.

So I let them build two 3/4 inch hoses with BSPP fittings. I got up early Monday to do this. I told them I needed two 24 inch lines. He handed them to me (made while I waited) and I paid for them, while my mind was screaming....................they look short.

Got them home and a quick dry fit told me my mind was right.:shocked: Instead of 24 inch lines, I needed 42 inch lines. So I got a male union fitting ($11)

So I got a male union fitting ($11)

to use what I had for one line. That didn't work either because I need a huge bend right where the union is.

to use what I had for one line. That didn't work either because I need a huge bend right where the union is. So I ordered, from Discount Hydraulic Hose, both lines of 42 inches, for $40 less than my local shop.:ashamed:

So I ordered, from Discount Hydraulic Hose, both lines of 42 inches, for $40 less than my local shop.:ashamed:

No wonder engineers make so much money...........guess they get more sleep!:thumbdown:

hugs, Brandi

Got them home and a quick dry fit told me my mind was right.:shocked: Instead of 24 inch lines, I needed 42 inch lines.

No wonder engineers make so much money...........guess they get more sleep!:thumbdown:

hugs, Brandi

Here are some similar links:

- Replies

- 0

- Views

- 946