kiotiken

Veteran Member

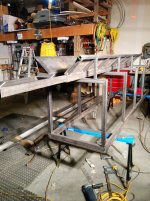

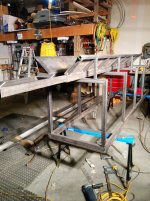

So my wife took the kids to visit her sister in Toronto this weekend... I've been thinking about building a firewood processor for a long time now, so it was time to get started. Like everybody else who builds one, I watched hundreds of youtube videos for ideas. After many design ideas, I finally settled on a very unique idea, KISS, Keep It Simple Stupid! I decided to simplify the design. My processor would split and advance the log at the same time, why add hyraulic motors, chains and rollers? My design is to use the splitters stroke to also advance the log to the next cutting position. It also uses my existing chainsaw to cut logs. I'm leaving it open to add a hydraulic saw in the future, but for now, my existing saw will do.

So far, I've bought half the steel I'm going to need. I've also bought a 15 hp engine, a 10 gallon hydraulic tank, a 4 inch log splitter ram and a few hoses. I still need to buy the two stage log splitter pump and steel for the 2, 4 and 6 way wedges. I'm at about $1300 so far, with another $1000 - 1500 to go. This is mostly going to be a picture thread as I slowly build this thing. Here's what I got done Friday night and Saturday...

I had to rip a piece of steel for runners. An hour and a 8 cutting disks later...

Slide to carry the log...

trough for the log

So far, I've bought half the steel I'm going to need. I've also bought a 15 hp engine, a 10 gallon hydraulic tank, a 4 inch log splitter ram and a few hoses. I still need to buy the two stage log splitter pump and steel for the 2, 4 and 6 way wedges. I'm at about $1300 so far, with another $1000 - 1500 to go. This is mostly going to be a picture thread as I slowly build this thing. Here's what I got done Friday night and Saturday...

I had to rip a piece of steel for runners. An hour and a 8 cutting disks later...

Slide to carry the log...

trough for the log

![IMG_20141023_235028[1].jpg IMG_20141023_235028[1].jpg](https://www.tractorbynet.com/forums/data/attachments/359/359220-432803f354519ed926360af8b8026b83.jpg)

![IMG_20141023_235048[1].jpg IMG_20141023_235048[1].jpg](https://www.tractorbynet.com/forums/data/attachments/359/359231-8c67dc61ac3a8abe25d3a93d5a7f3212.jpg)

![IMG_20141026_233424[1].jpg IMG_20141026_233424[1].jpg](https://www.tractorbynet.com/forums/data/attachments/361/361533-e21b9d75616bc359be88cc57e555c5d0.jpg)

![IMG_20141027_220309[1].jpg IMG_20141027_220309[1].jpg](https://www.tractorbynet.com/forums/data/attachments/361/361539-81c59ed58c20a413bf3a36301de10fcb.jpg)

![IMG_20141027_220403[1].jpg IMG_20141027_220403[1].jpg](https://www.tractorbynet.com/forums/data/attachments/361/361546-e58c0f8046f9fbe05d66ba2a4d1e81e3.jpg)

![IMG_20141027_220431[1].jpg IMG_20141027_220431[1].jpg](https://www.tractorbynet.com/forums/data/attachments/361/361553-e0b9916a90359a2a4d8fa7233afa3543.jpg)

![IMG_20141027_220417[1].jpg IMG_20141027_220417[1].jpg](https://www.tractorbynet.com/forums/data/attachments/361/361558-1f95c635537d2504e399d0f152529ce9.jpg)

![IMG_20141028_235042[1].jpg IMG_20141028_235042[1].jpg](https://www.tractorbynet.com/forums/data/attachments/361/361995-22e10d0f94e44ebed32e1756bd8ec837.jpg)

![IMG_20141028_235111[1].jpg IMG_20141028_235111[1].jpg](https://www.tractorbynet.com/forums/data/attachments/362/362009-1388d46925939af8f170378c75e3f666.jpg)

![IMG_20141028_235122[1].jpg IMG_20141028_235122[1].jpg](https://www.tractorbynet.com/forums/data/attachments/362/362019-bf2e03c1cd6ba17bde665642b092d516.jpg)