LouNY

Super Star Member

- Joined

- Jul 4, 2015

- Messages

- 14,419

- Location

- Greenwich, NY

- Tractor

- Branson 8050, IH 574, Oliver 1550 Diesel Utility (traded in on Branson) NH 8160. Kioti CK2620SECH

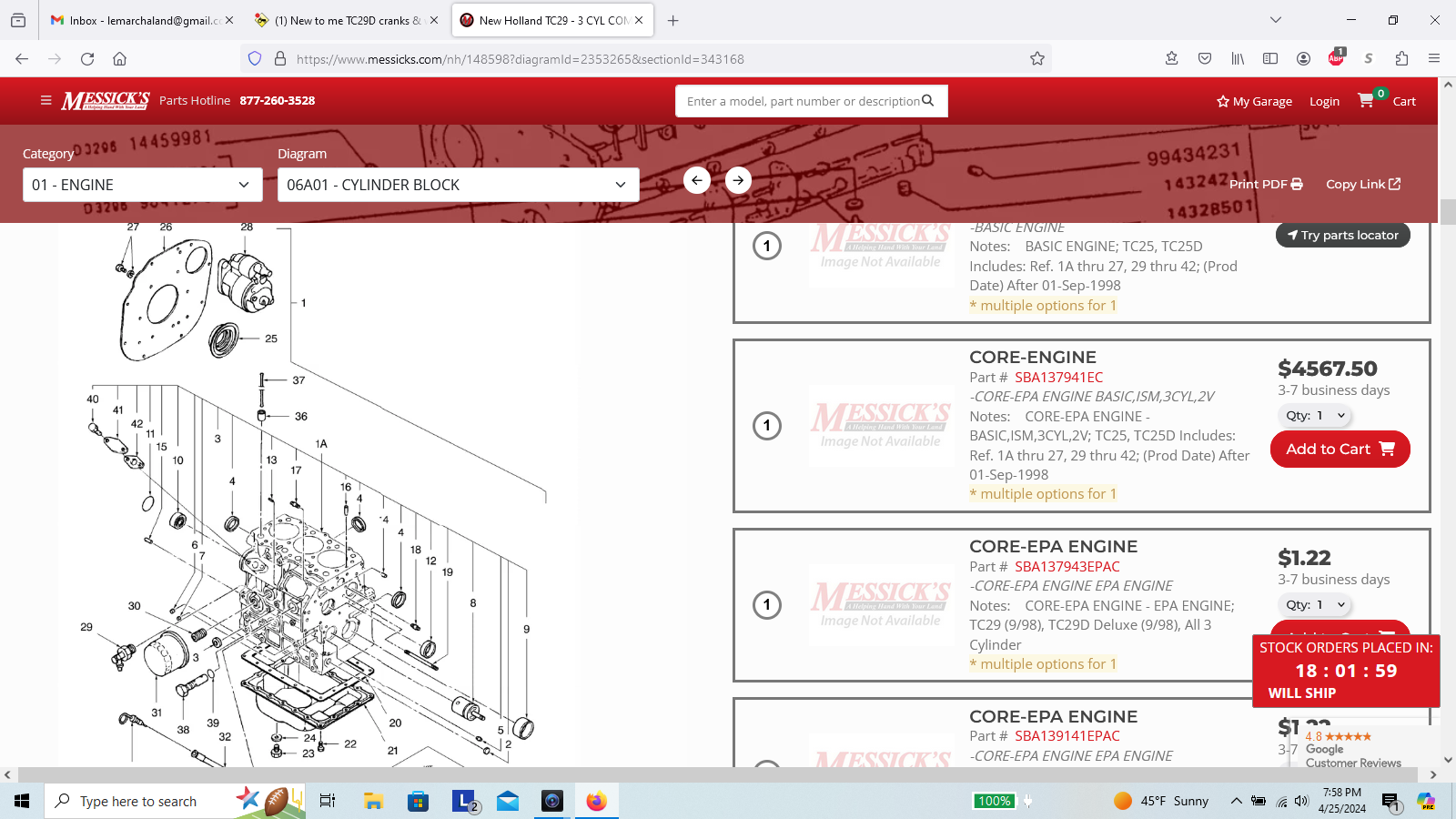

So a basic block looks to be $4600

I drained the full tank that was in the tractor with the thought of moisture in mind. I will remove the cup and cover with a rubber floor mat or something of the like for storage.I mentioned condensation in fuel lines in a previous post. My BTDT with TCs is that there is a spill cup with a drain hose around the filler and under the hood. Tree duff can clog the drain and rain water will fill the cup above the rim of the cap.

This will by thermal expansion of air/vapor in the tank to siphon that water into the tank where it will settle as expected. I've had to thaw lines to clear them twice. (not tarped in Winter back then, Doh!) My prevention is to remove the cup (1) and/or close the hood on a rag or bag (another 1) to overlap the cup accordingly & keep detritus or water from building up in it.

Prior storage can have as much effect as prior maintenance on how quickly a long-parked tractor starts up, how well it runs, or whether it needs serious work. (o/haul. short block, etc)

btw, while my manuals are for the newer DAs the wiring is pretty much the same, as are most of the mechanicals. Did we ask what the hours are or which FEL? (7308?)

If this were me, I would use oldgrind‘s advise coupled with the pumpguysc. You bled the tank, now bleed the rest out to the injectors. Then do a cheap injector test to see if they spray or squirt. Then I would load test the battery. If the amps are low, the starter won’t spin fast enough and you will get a low compression reading.I drained the full tank that was in the tractor with the thought of moisture in mind. I will remove the cup and cover with a rubber floor mat or something of the like for storage.

Copy that on the manuals thank you for the offer! Hour meter only reads 1136 or something low like that.

Front end loader decals are painted over but the controls say it’s a yanmar and looks to be a nice one but I’m used to older tractors 90’s and older vintage though…

If you've pulled a head off you can certainly do the job. You'll need a torque wrench and a ring compressor or appropriately sized band clamp.Oil smells ok to a neighbor and myself. No significant diesel smell to it

I’m thinking new rings at least as most are mentioning.

Rings can be replaced without “splitting the tractor”?

CAN rings be replaced by a home mechanic (me) with good assistance from online (YouTube and all of you great people!)

I see someone mentioned a basic block for near $5k

Rings and a head gasket will be a much more reasonable rout right??

So at this point I’m starting some good cleaning and I got the front bucket off to make it easier to move tractor into our small shop

Anyone have a good YouTube video they’d recommend towards rings or rebuilding or anything strongly recommended? I’ve had valve cover and head off of another tractor so I’ve been at least to piston heads on another tractor and have a basic understanding of what to do. I watch motortrend channel haha

This smell the oil test dosnt really work. Every engine I have ever smelled the oil on smelled a bit like the fuel it burned.Smell the oil from the dipstick. If it smells like diesel either that seal is leaking or it's been cranked for a long time with rings not sealing

ok I like that encouragement. I’ve got a torque wrench. WHAT SIZE & TYPE RING COMPRESSOR should I buy?? 3” amazon special or ?If you've pulled a head off you can certainly do the job. You'll need a torque wrench and a ring compressor or appropriately sized band clamp.

You'll need to buy at minimum a ring set (obviously), a head gasket, an oil pan gasket, a tube of assembly lube, possibly intake and exhaust manifold gaskets, and you can consider new rod bearings but at 1100hrs that's probably not necessary so long as you are **** about locations and orientations of ALL individual parts.

Suggest you do one piston at a time to keep everything straight

How do you typically keep things oriented do you mark with a punch with dots or ??IDK if your aware of it or not but u have to pay attention which way the pistons go in..

Some will have an arrow on them, but u still have to know which way the arrow goes..

Also, mark your rod and rod caps 1/1, 2/2, 3/3..

U might wanna buy some “plasti-gauge”., to get the correct rod bearings..

(Google it)

Good luck

No. Ball hone in 2nd pic OR stone type hone in 3rd pic. IMO ball hone is easier to use and less likely to take off too much material.Also is a ridge reamer the same as a cylinder hone??

1100 hours, something just isn't adding up (although the hours may not be real).I bought a very similar Ford tractor model under exactly the same circumstances. Turns out the Ford fuel flow lever at the filter in the motor compartment points 90 degrees off of the direction for flow. The fuel was shut off. 2 minutes after I paid the guy, I turned the valve and drove it onto the trailer. Only his wife was mad...

I definitely agree that something isn’t adding up. Three sets of rings failing at the same time, with similar test results? What is the expected number 300ish, probably close enough to get it to puff.1100 hours, something just isn't adding up (although the hours may not be real).

If you have a place in the intake manifold that you can't melt, blow either a hot hair dryer or heat gun directly into the intake manifold when cranking it over and attempting to start it.

Endoscope cameras can be a tad cheaper and always handy for something.Been following this thread. Have you drained the oil and checked for particles ? With as low of hours, you stated it has fuel in the lines , and clean intake. It’s sounding like someone ran it low on oil and smoked that engine maybe. Only way I see all cylinders being that bad.

As stated do a leak down test. Napa , harbor freight etc sell the kits. If it were me I’d be buying a bore scope off Amazon ( I paid $90 for one ) and looking in the glow plug holes if possible. I would drain and screen the oil. With low compression and possibly needing to remove pistons. I would just bite the bullet and pull the pan. I’d be curious to see if it was oil starved.