Richard, if it gets you going without anything going wrong, then everybody wins - no problem :thumbsup:

Skyhook, good call on the piece of plywood - most jacks these days have such wimpy little platforms - I have an old Walker 1-1/2 ton that's spoiled me for most of the newer stuff - platform is just over 7" square, I used to balance VW engines on it while R&R them, never dropped one :thumbsup:

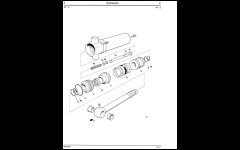

I bet I've looked at that exploded view at least 20 times, never did see any little un-numbered blobs anywhere - sure would have been nice if that allen screw were documented anywhere but the grapevine

Richard, sorry to hear about your health problems - guess I'm blessed, I'll be 70 this month and so far the only major hiccup has been major rotator cuff repair/complete biceps re-attachment (plus 3 little pins for anchor points - took me out of most of the fun activites for a year, but now it's good as new :thumbsup:

The problem(s) I foresee with your new removal plan -

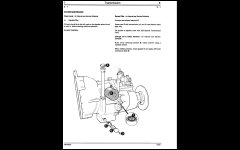

(1)it doesn't look like you would have enough "slop" in the rod end pins to allow the cylinder body to drop down far enough to clear the upper trunnion joints - plus, unless you can drop both ends evenly, something would likely bind up -

(2) On mine, the boom needs to be centered in order to allow both rod ends to swing away from the boom far enough to clear -

(3) usually those pins are hard enough to get out WITHOUT having a bind on them -

(4) I had my full strengh when I did mine, and it was still really hard to move rods in and out without hoses hooked back up and pump running.

You did get me thinking about options though - you might be able to get away with your method if there is something directly above the REAR of each cylinder -

(0) - Boom centered, bucket on the ground

1 - ratchet strap around rear of each cylinder individually, holding that end UP, hoses off.

2 - Drop the lower plate (only)

3 - Floor jack centered under one trunnion - this may work better if you take a piece of scrap wood as thick as the depth of the trunnion, hole saw the center to slip fit the trunnion, trim the board to "snuggle" down into the jack platform - this should improve control while removing

4 - Support the cylinder on its lower trunnion, with jack and "snuggle board" -

5 - NOW, remove the pin from the rod end, swing rod end clear of swing tower and drop that cylinder straight down (gently)

6 - Repeat for the other side.

Re-installing - Ask your rebuilder to COLLAPSE both cylinders so the rod ends don't stick out enough to interfere with the swing tower - looks like there may not be enough room to "splay" the cylinder bodies enough to clear the swing tower on both sides - then...

1 - using your "snuggle jack", raise each cylinder up into its upper trunnion socket and leave maybe 1/8" of play or less (not too tight to swing the cylinder)

2 - Again, support the rear of the cylinder with a ratchet strap so the lower trunnion is clear, and lower the jack

3 - Repeat for the other side

4 - Now, with just some minor wiggling, you should be able to jack up the lower plate and get it lined up with both lower trunnions and the 4 studs - run all four nuts up snug for now.

5 - hook up all hoses - remember there will be AIR in the system, so be VERY sure you don't get any body parts near any "pinch points" - from hear on, unless you're "super-McGuyver", you'll probably need a helper -

6 - Now that you have both cylinders trapped you can remove the ratchet straps - run a short length of rope thru one of the rod end eyes (better to get that ROPE in the wrong place than your fingers)

7 - Pull sideways on the rope just enough so the rod end clears the tower, and "feather" the swing control back and forth til you get the eye lined up with the pin hole. You may need to go back and forth several times til most of the air gets out of the system - both cylinders will try to move, one in and the other out. Watch for any interference with the one you're NOT trying to pin. That other one will probably NOT have enough space to splay wide enough to just STAY out of your way. Once you get some extension on the cylinder, you can move the rope to the shaft so it's out of the way of the pin hole. This will continue to keep your fingers out of the way.

You will also need to rotate the rod end with a lever (through the pin hole) til it will slide into the pin slot on the swing tower.

8 - The second cylinder should cooperate more than the first, since you won't need to worry much about the other side once it's pinned.

If you haven't already, finish tightening the nuts holding the lower plate. At this time I'd put 4 MORE nuts on to protect those threads.

Once again, be VERY careful where you put your body parts during this, especially when the pump is running - I had two of my millwrights injured in the last few years from NOT paying close enough attention during similar operations. I've been doing this kind of stuff in heavy industry for the last 35 years and running a full maintenance crew for the last 10, seen more crap than I ever wanted to...

Hope that helps you work out a method - gotta quit for now, for some reason Firefox seems to be hogging memory and it took me over an HOUR to get this much written - :thumbdown: ...Steve