number9L

Gold Member

I have a Kubota L3800 with FEL. I am wanting to add a Top-n-Tilt setup but want to take my time and plan this out and try and get it "right" (not have regrets) the first time.

There isn't a lot of room on the L3800 to mount the valves in a clean way and I'd really like to use a loader type valve / joystick with Float for running the TnT. I'd like to have the Float on the top link to allow Rotary Cutter, Finish Mower and Box Blade follow the ground. I want to add a Power Beyond valve/remote as well while I am at it, but am fine with a single lever for that function or using a diverter valve may be even better. I want as clean an install as I can work out.

These two valves look like they might fit well down in between the seat and RH fender and work well for what I have in mind. I know I'll have to do some fab work to get them mounted and creative hose routing, but that's fine as I am not in a bug hurry to throw them on in the next week. I want to take my time and do it well and I suspect hose routing will be the most challenging part of this process.

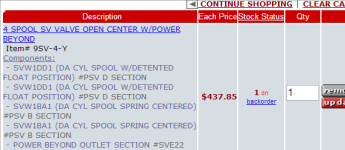

Surplus Center - 2 SPOOL COMPACT 10 GPM JOYSTICK CONTROL VALVE

Surplus Center - 2 SPOOL 14 GPM PRINCE LVR JOYSTICK LOADER VALVE

This one has a 14GPM rate, would that work ok with my tractor's 6.3GPM pump?

I am wondering if I should go ahead while I am doing all this and add a 3rd function to the FEL as I can see that I may want a grapple down the road. I'd want to do a diverter valve for this one so I can just use the FEL joystick.

I've read threads about others using diverter valves where the button to switch the valve is momentary. Is there valves that allow the use of a toggle switch? That seems like it would be more intuitive, just flip the switch and work the stick as needed, then flip it back as opposed to holding the momentary button in the whole time. Maybe not, I really don't know.

I'm just trying to think ahead at all the possibilities so I don't wish I'd done something different once I get it installed and using it.

...

There isn't a lot of room on the L3800 to mount the valves in a clean way and I'd really like to use a loader type valve / joystick with Float for running the TnT. I'd like to have the Float on the top link to allow Rotary Cutter, Finish Mower and Box Blade follow the ground. I want to add a Power Beyond valve/remote as well while I am at it, but am fine with a single lever for that function or using a diverter valve may be even better. I want as clean an install as I can work out.

These two valves look like they might fit well down in between the seat and RH fender and work well for what I have in mind. I know I'll have to do some fab work to get them mounted and creative hose routing, but that's fine as I am not in a bug hurry to throw them on in the next week. I want to take my time and do it well and I suspect hose routing will be the most challenging part of this process.

Surplus Center - 2 SPOOL COMPACT 10 GPM JOYSTICK CONTROL VALVE

Surplus Center - 2 SPOOL 14 GPM PRINCE LVR JOYSTICK LOADER VALVE

This one has a 14GPM rate, would that work ok with my tractor's 6.3GPM pump?

I am wondering if I should go ahead while I am doing all this and add a 3rd function to the FEL as I can see that I may want a grapple down the road. I'd want to do a diverter valve for this one so I can just use the FEL joystick.

I've read threads about others using diverter valves where the button to switch the valve is momentary. Is there valves that allow the use of a toggle switch? That seems like it would be more intuitive, just flip the switch and work the stick as needed, then flip it back as opposed to holding the momentary button in the whole time. Maybe not, I really don't know.

I'm just trying to think ahead at all the possibilities so I don't wish I'd done something different once I get it installed and using it.

...