woodlandfarms

Super Member

- Joined

- Jul 31, 2006

- Messages

- 6,149

- Location

- Los Angeles / SW Washington

- Tractor

- PowerTrac 1850, Kubota RTV x900

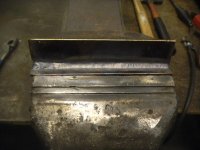

OK, my setup....

Scratch Start Tig

100% Argon

#6 Cup

Matheson Select 3.32 Blue Tip E3 Tungsten Electrode

Everlast PowerArc 200st

Setup for 16 Guage Mild Steel

25 Amps on Meter

15CFM on Argon

Results - A lot of burn through.

Setup for 24 Guage Copper

20 Amps

15CFM

Results - Incineration. By the time I got a puddle I burned through. I tried laying some filler copper on top, see if that would help, torched right through.

While I am a beginner, I am not sure the issue is me. Maybe 20 Amps is too much for this stuff (WOO HOO I get to buy a real tig machine) but I think not. All the charts and while none I have found mention 24 guage copper, it seems to me that I need a lot more than 20 amps to make it happen.

Looking for any and all comments.

Scratch Start Tig

100% Argon

#6 Cup

Matheson Select 3.32 Blue Tip E3 Tungsten Electrode

Everlast PowerArc 200st

Setup for 16 Guage Mild Steel

25 Amps on Meter

15CFM on Argon

Results - A lot of burn through.

Setup for 24 Guage Copper

20 Amps

15CFM

Results - Incineration. By the time I got a puddle I burned through. I tried laying some filler copper on top, see if that would help, torched right through.

While I am a beginner, I am not sure the issue is me. Maybe 20 Amps is too much for this stuff (WOO HOO I get to buy a real tig machine) but I think not. All the charts and while none I have found mention 24 guage copper, it seems to me that I need a lot more than 20 amps to make it happen.

Looking for any and all comments.