Teachu2

Platinum Member

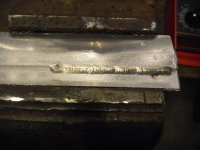

I just bought this scratch start Tig torch a couple months ago. Really like it.:thumbsup:

WP 26V 25R 25' 200Amp Air Cooled TIG Welding Torch Gas Valve Ready to Go Package | eBay

http://www.ebay.com/itm/140514184508?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

That looks pretty sweet.