"Is your X-Y table from a milling machine or something you came up with otherwise?"

Originally I was trying to "get more" out of my old taiwanese DP, and bought this

6" x 18-1/2" Compound Slide Table | Grizzly Industrial -

Before that went too far I discovered just how futile THAT idea was, so the table sat under a bench (still in its box) long enough for me to almost forget I HAD it - then my company INSISTED that I make a bunch more money working OT, so naturally along came this

Heavy-Duty Mill/Drill with Stand and Power Feed | Grizzly Industrial

followed over the next year or so of continued OT by a couple welders, plasma cutter, the already documented mag drill, etc -

Then, after I built the "MDVT" and found it to be even more useful than I'd thought, I "remembered" that x-y table as I was getting ready for the "terrain-adjustable legs" phase of my "container cover" project - after a couple "minor" tweaks on the original "MDVT" I found room for the x-y table, 'bout the same time HF had these on a coupon for $9.99 each

Drill Press Vise w/ 4" Jaw

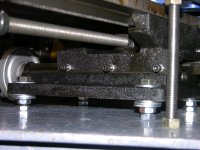

There was a slight "height discrepancy" problem, which got resolved with thru-bolts into the steel table and some jam nuts (see pics) and I'm still watching CL for a burned out TABLE model DP I can steal the elevation stuff out of (guess that'll be "phase III") - but for now, anything I can clamp to that x-y table, either with the DP vises or a milling machine clamp set, I can do repetitive holes over a 12" range without re-clamping.

As it sits right now, the x-y table is aligned in its height axis(Z) so mag drill cutter height is constant over the length of table travel, so theoretically I could put the right adapter on the mag drill and do small milling jobs, but considering my OTHER options that seems kinda silly, even for MY demented brain :confused2:

The lead screw on that table is exactly 10TPI (or close enough without needing real machine shop accuracy) so if you want holes on 3/4" centers, you crank the table 7-1/2 turns and drill, repeat as necessary - accuracy was good enough on the messy pic I showed, that all I did over 12" in order to get both sides' holes to line up was to transfer a scribe line to both sides of the tube at one end, and line up the first hole(s) while holding some tension against the table travel. Then it was just "1-2-3-4-5-6-7-8-9-10 Drill, repeat..."

Afterward all 13 pairs of opposing holes (I used a 13mm cutter for 1/2" bolts, 0.0118" oversize) lined up fine. They're used for "coarse" adjustment of height, "fine" is accomplished by 1" acme threaded rod between the tube and the C-channel feet. (see earlier pics)

Given the mess annular cutters make (and the fact that my mill currently has to live in a WOOD shop)

I find it's less frustrating to make that mess ELSEWHERE, and clean it up with a magnetic sweeper.

I'm sure that as the "saga of my life" continues to unfold (I hope, anyway

) that the mill will find a better home, but for now this works for me - plus, where's the FUN in life without a challenge or 27?

...Steve