I'm looking for some input on building a 3pt ballast box for my Branson 2610h. My first, and main question is concerning how heavy to make it. I plan to make it out of concrete. Simple rectangle/cube shape. Weight will be centered at or just behind the pivot ends. My tractor is rated to lift approx 1500 at the link ends. Is 600lbs a good goal? Or is there some formula I should be using to calculate leverage effect on front axle, etc?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3pt ballast design questions

- Thread starter PreacherM

- Start date

- Views: 9669

More options

Who Replied?

/ 3pt ballast design questions

#1

amhicks21

Silver Member

600 should be plenty for a tractor that size. the tractor i run the most will handle its full 2200lb lift capacity with a 1200lb implement behind it just fine. Just curious though, is there a reason you wouldnt want to do fluid filled rear tires instead? I built a 1000lb weight box a while back for snow plowing to run along with fluid in both the front and rear tires for the sake of traction, but thats the only use it gets. The box i built isnt completely full of concrete but has a compartment for storage. I made up some extra weight by tossing a bunch of scrap steel in with the concrete. I think if i wasnt going for something so purpose built for snow plowing i wouldve just filled it with sand and scrap steel so i could repurpose it later

if i wanted.

if i wanted.

WranglerX

Super Member

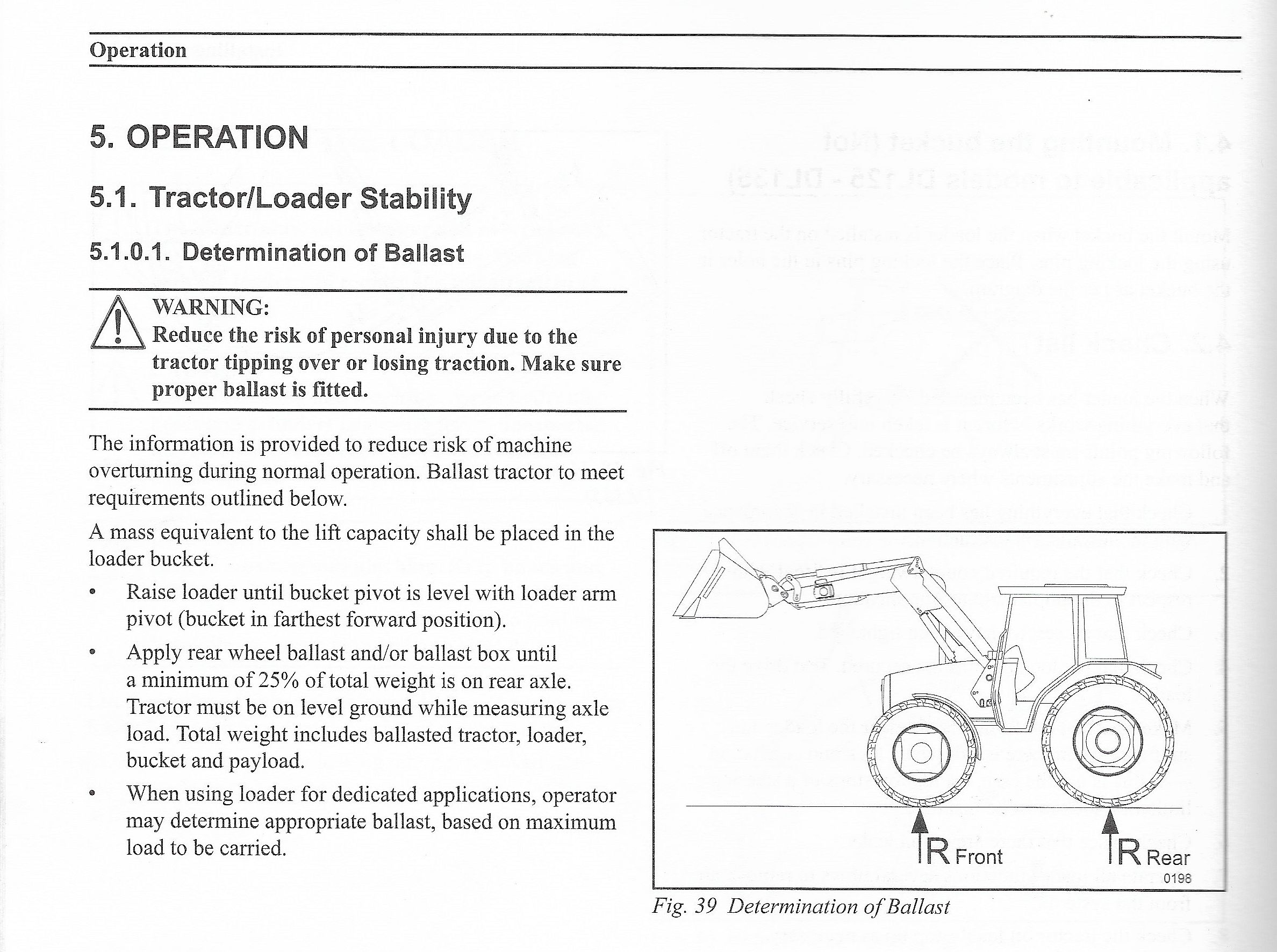

Check owners manual, mine has a some what dubious wording on how to calculate needed weight.... I simply made a steel box out of angle iron and flat plate and set it up to match my CAT 1 QH... Box is 2x2x1 feet (4 cubic feet) and weigh in maybe 600 pounds (in some cases it may be too big for tractor size) .... By all information gathered on i-net concrete weighs in at about 150 pounds per cubic foot....

But the are other options, may be cast iron bar bell weights.... Actual tractor "suit case" weights, maybe old engine block, box of rocks...

Caped off tubes (spray can tops) are ABS pipe inserted all way to bottom as tool holders...

Also site search for "ballast weight" may turn up a lot of different ideas or solutions...

But the are other options, may be cast iron bar bell weights.... Actual tractor "suit case" weights, maybe old engine block, box of rocks...

Caped off tubes (spray can tops) are ABS pipe inserted all way to bottom as tool holders...

Also site search for "ballast weight" may turn up a lot of different ideas or solutions...

Last edited:

Ken45101

Elite Member

- Joined

- Feb 14, 2009

- Messages

- 3,679

- Location

- southern Ohio

- Tractor

- Kubota M5040, M9540, B21 TLB, B2710, RTV900, JD 325 Skid steer, KX-121-3 mini excavator

I strongly recommend filled rear tires as a first step, beet juice is a good fill.

My first tractor, a Kubota M4700 (45 hp) was 2wd and did fine without rear weight until I added a loader. It performed poorly with the loader and was dangerous going downhill with a loaded bucket. I tried a 55 gallon drum of concrete on the 3pt, it helped a bit but not enough. That was about 1100 pounds.

That tractor was replaced by a similar sized M5040, 4wd, and loaded rear tires. No problems at all using the loader. Of course the 4wd he3ps but it never feels light in the rear. IIRC, there may be 800# per tire. Loading the tires has the advantage of putting the weight on the tire tread, not on the tractor frame, bearngs, etc. Likewise my bigger M9540 has loaded rear tires. No loader on it but it pulls a 4400# batwing mower and a round basler up nd down our steep hills. I've had both tractors over a dozen years now.

The barrel full of concrete has been sitting down in a junk pile for a long time if anyone wants it, LOL.

Ken

My first tractor, a Kubota M4700 (45 hp) was 2wd and did fine without rear weight until I added a loader. It performed poorly with the loader and was dangerous going downhill with a loaded bucket. I tried a 55 gallon drum of concrete on the 3pt, it helped a bit but not enough. That was about 1100 pounds.

That tractor was replaced by a similar sized M5040, 4wd, and loaded rear tires. No problems at all using the loader. Of course the 4wd he3ps but it never feels light in the rear. IIRC, there may be 800# per tire. Loading the tires has the advantage of putting the weight on the tire tread, not on the tractor frame, bearngs, etc. Likewise my bigger M9540 has loaded rear tires. No loader on it but it pulls a 4400# batwing mower and a round basler up nd down our steep hills. I've had both tractors over a dozen years now.

The barrel full of concrete has been sitting down in a junk pile for a long time if anyone wants it, LOL.

Ken

I already have fluid filled rear tires. Just moving dirt or hravel that is sufficient. I want some additional weight that I can put on, mainly for when I use pallet forks or possibly a grapple in the future. I want to gain some stability at near max lift, but mostly looking to save the front axle.

At the same time, I don't want it to be extremely heavy, since I'll be putting a 2" receiver in it for pulling trailers. Need to allow some capacity for handling tongue weight.

At the same time, I don't want it to be extremely heavy, since I'll be putting a 2" receiver in it for pulling trailers. Need to allow some capacity for handling tongue weight.

WranglerX

Super Member

Search forum the is several posting of ballast weight on receiver hitches.... Only thing you have to be pretty accurate backing into hitch arrangement, not much room for misalignment...

Last edited:

metalbender

Veteran Member

A large ammo can filled with Lee and Lyman lead ingots gave me around 600 lbs. That on the three point will give more force on the tires than all the beet juice you can fill.

Raul-02

Veteran Member

- Joined

- Aug 23, 2021

- Messages

- 1,467

- Tractor

- kioti DK4710 SE HST CAB

I had a wood stove that I never used. it came with the building. It's huge 40 sumpin inches on one side, nothing on it is thinner than 1/4". it weighs maybe 400 pounds all by itself I welded tabs to it filled it with rocks and now it is so heavy that I can do this and there is no rear wheel liftIs 600lbs a good goal? Or is there some formula I should be using to calculate leverage effect on front axle, etc?

inpo44

Bronze Member

- Joined

- Apr 6, 2012

- Messages

- 54

- Location

- Mid Missouri

- Tractor

- New Holland TC45D, TN60DA, Workmaster 37

I ended up using approximately half of my tractors 3 point lift capacity on my ballast build. My New Holland TC45D has a 3pt rating of 3275lbs at the pins and 2330lbs at 24” behind the pins. I chose a target weight of 1500 -1600 lbs with a center of gravity at 12” behind the pins. A key factor was I wanted to be able to move the ballast around with loader/pallet forks. The capacity of tractor’s loader (NH 16LA) is 2317 lbs at the pins and 1759lbs at 24”. I can safely move it around

with my 550 lbs box blade on the the 3 point and 600 lbs of cast iron weights on the wheels.

with my 550 lbs box blade on the the 3 point and 600 lbs of cast iron weights on the wheels.

gabby

Gold Member

Kill two birds with one stone: Build or buy a 3 pt fork lift attachment, then build a palletized ballast box to carry with the forks. You will find other good uses for the forks in addition to carrying your ballast. You can build a wood box with 4x4 skids underneath and filli lt with dirt, rocks, rubble, etc. for free. Or you can fill it with concrete but that's not free!

DaBear3428

Platinum Member

is there anything wrong with adding suitcase weights or scrap iron with notches to a box blade? seems like it would help the box blade function and add counterweight to the FEL, and not add another implement to the growing pile.

Renze

Super Member

My loader lifts 1200kg and i use about 650-700kg rear ballast, all steel suitcase weights on a rack, so it lifts above the drawbar of the bale trailer. For loading bales this was perfect, but when digging i would like a bit more.A couple of manuals recommended a 3-point ballast of a weight that was about 2/3 loader capacity.

Bruce

With the other tractor i loaded the 3pt earth scoop with muck when loading the spreader, quite heavy (it had a safety latch in upper position so when jamming it into the highwall of the muck heap i could increase ballast after loading the first few loads. Because the tractor was a 1963 Deutz D50 without powersteering, every pound behind the rear axle to take weight off the front was welcome)

The drawback of using that big rear scoop as ballast was that you often hit something when reversing, because your mind was on the loader bucket clearing the spreader sideboards when swinging over it at a T junction between the barns...

If the 3pt must carry it, i would not go beyond 2/3 of the lift capacity, because if your oil pump strains when correcting the 3pt hitch lift height, you momentarily loose hydraulic power on the loader and the rear end heats up pretty bad during the day: there have been days that i unloaded the 1.5 cubic yard of solid black muck a bit because the tractor needed full rpm to lift it to max height.

It should be able to lift the rear ballast at slightly over low idle.

Vigo327

Platinum Member

is there anything wrong with adding suitcase weights or scrap iron with notches to a box blade? seems like it would help the box blade function and add counterweight to the FEL, and not add another implement to the growing pile.

I think the main advantage of a dedicated 3pt ballast implement is that it doesn't create the maneuverability challenges of a normal implement.

I have a tiny B6100 Kubota that I use a 60" box blade behind. The box blade probably weighs 300-350. I bolted a 113lb 54" loading dock bumper onto the back of it and it both makes the box blade cut quicker/better, and massively increased my counterweighting since the 113lb gain (~30% gain?) is at the very back of the box. Now all i have to do is increase my loader pressure so i actually NEED that extra counterweight!

Finally got the weight poured yesterday. Will wait another day or so to try it out, then paint the metal parts (should a done that first). Weighs in right at 600 lbs. Center of gravity is about 2 inches behind the pins. I've got a 2" receiver embedded in the concrete also. Fabricated an extended pin in order to be able to lock the hitch in place.

DaBear3428

Platinum Member

I'm thinking that the box blade does not interfere with maneuvering, it actually helps keep me from backing into brush and breaking my lights on the back of the tractor.I think the main advantage of a dedicated 3pt ballast implement is that it doesn't create the maneuverability challenges of a normal implement.

I have a tiny B6100 Kubota that I use a 60" box blade behind. The box blade probably weighs 300-350. I bolted a 113lb 54" loading dock bumper onto the back of it and it both makes the box blade cut quicker/better, and massively increased my counterweighting since the 113lb gain (~30% gain?) is at the very back of the box. Now all i have to do is increase my loader pressure so i actually NEED that extra counterweight!Right now it's a measly 750psi.. Im thinking 1200-1300 oughta find the next weakest link.

oosik

Epic Contributor

When I was deciding on an upgraded tractor - I considered a weight box on the 3-point. But a weight box DOES nothing. Instead I went with Rimguard filled rear tires ( 1550# ) and a 1000#+ rear blade.

These two upgrades successfully handle the total lift capacity of my FEL and grapple. I can lift and move 3000#+ with the FEL and grapple.

I have 80 acres and a mile long gravel driveway. I'm not limited by confined spaces.

These two upgrades successfully handle the total lift capacity of my FEL and grapple. I can lift and move 3000#+ with the FEL and grapple.

I have 80 acres and a mile long gravel driveway. I'm not limited by confined spaces.

Most of my heavy lifting will be done in tight areas. I built this ballast box for around $100 bucks. I'm not buying a box blade until prices come down or i find a used one. Also, this way when cutting firewood i can hook the trailer on behind and still have the weight for extra traction after I unhook. It certainly has limited usefulness, but it's also cheap to build, takes little space, and won't wear out very quickly!When I was deciding on an upgraded tractor - I considered a weight box on the 3-point. But a weight box DOES nothing. Instead I went with Rimguard filled rear tires ( 1550# ) and a 1000#+ rear blade.

These two upgrades successfully handle the total lift capacity of my FEL and grapple. I can lift and move 3000#+ with the FEL and grapple.

I have 80 acres and a mile long gravel driveway. I'm not limited by confined spaces.