OP

muddstopper

Veteran Member

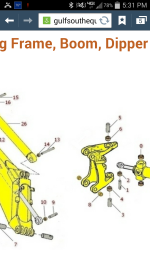

I have been trying to figure out the amount of force I would have at the base of a boom 16ft long. What i think might be correct, but not 100%, sure so I am going to throw it out there as see what others have to say.

I am looking at this as the boom having a lever effect with the root boom cylinder being the fulcrum. With one end of the boom being fixed and the lift cylinder being 2ft from that fixed point, I should have a leverage effect of 8:1(16ft/2ft). Using a 3in bore cylinder at 3000psi should give me a lifting force of 10tons or 20,000lb, /8= 2500lbs of total lift capacity. The total lift weight would have to include the weight of the boom and grapple. This would be with the boom fully extended and at a horizonal position and weight loads would be greater as the dipper boom is pulled closer to the root boom, or as the root boom is raised or lowered from the horizonal position. Does this sound reasonable?? Actual lift capacity would change if the root cylinder was mounted closer or farther than the 2ft number I used as mounting of the root cylinder.

I think this is the way to figure the lift capacity of the boom and cylinders I need to get the lifting force I want. I just dont know how to figure out the actual stress that would be applied to the base of the boom at the swivel. I found that the loader in one of the links already posted, used a shaft of 3in dia, but was only rated for 800lbs with a 9.5ft boom. I found another boom that used a 4in shaft for the swivel, but had a 1200lb capacity with a 11.5ft reach. A 24in diax14ft southern red oak will weigh right at 2500, and I think this would be the heaviest possible load I might encounter. At actual loaded height the dipper boom would probably be at less than half extention so total swivel stress would be calculated at around 12ft of boom lenght. =15000load at swivel base. It seems the closer the load the less the stress at the base, which would coincide with some of the load charts I have found. Well now I am rambleing, Someone tell me if I'm on the right path.

I am looking at this as the boom having a lever effect with the root boom cylinder being the fulcrum. With one end of the boom being fixed and the lift cylinder being 2ft from that fixed point, I should have a leverage effect of 8:1(16ft/2ft). Using a 3in bore cylinder at 3000psi should give me a lifting force of 10tons or 20,000lb, /8= 2500lbs of total lift capacity. The total lift weight would have to include the weight of the boom and grapple. This would be with the boom fully extended and at a horizonal position and weight loads would be greater as the dipper boom is pulled closer to the root boom, or as the root boom is raised or lowered from the horizonal position. Does this sound reasonable?? Actual lift capacity would change if the root cylinder was mounted closer or farther than the 2ft number I used as mounting of the root cylinder.

I think this is the way to figure the lift capacity of the boom and cylinders I need to get the lifting force I want. I just dont know how to figure out the actual stress that would be applied to the base of the boom at the swivel. I found that the loader in one of the links already posted, used a shaft of 3in dia, but was only rated for 800lbs with a 9.5ft boom. I found another boom that used a 4in shaft for the swivel, but had a 1200lb capacity with a 11.5ft reach. A 24in diax14ft southern red oak will weigh right at 2500, and I think this would be the heaviest possible load I might encounter. At actual loaded height the dipper boom would probably be at less than half extention so total swivel stress would be calculated at around 12ft of boom lenght. =15000load at swivel base. It seems the closer the load the less the stress at the base, which would coincide with some of the load charts I have found. Well now I am rambleing, Someone tell me if I'm on the right path.