You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I got a Tractor!

- Thread starter The Chicken

- Start date

- Views: 16718

More options

Who Replied?

/ I got a Tractor!

#21

woodchipper

Silver Member

- Joined

- May 17, 2011

- Messages

- 247

- Location

- Campbell's Bay, Qu饕ec, Canada

- Tractor

- 1965 JD 710; 2000 Universal 643DT 4wd, loader, cab with heat:), 1983 MF 50F Backhoe 2wd.

Congrats on your new "industrial" tractor. I can see that you are of the most courageous type in willing to put back to life this machine!:thumbsup:

As you own a lathe and milling machine, this bushing replacement will only be a few hours of your time, with very little money down. Go for it!

Did you have a look at the engine already? Because if it has not turned over for a long time, many parts could be seized up!

Therefore, I would first start by removing the oil pan, and the cylinder head. No lubrication, rusty surfaces are just going to aggravate things very quickly. Also, after doing so, and assuming it will be not much to have the engine turning, I would take the fuel pump out and rebuild it. the seals will certainly be done...

So first turning the engine over, then fuel delivery, and last a spark (ignition)!

If you take your time and do it well the tractor may end up being a keeper. From your first posted picture, it really does need a lot of TLC...

Good luck, and keep us posted with your progress (and perseverence!), and accompanying pictures of course!

As you own a lathe and milling machine, this bushing replacement will only be a few hours of your time, with very little money down. Go for it!

Did you have a look at the engine already? Because if it has not turned over for a long time, many parts could be seized up!

Therefore, I would first start by removing the oil pan, and the cylinder head. No lubrication, rusty surfaces are just going to aggravate things very quickly. Also, after doing so, and assuming it will be not much to have the engine turning, I would take the fuel pump out and rebuild it. the seals will certainly be done...

So first turning the engine over, then fuel delivery, and last a spark (ignition)!

If you take your time and do it well the tractor may end up being a keeper. From your first posted picture, it really does need a lot of TLC...

Good luck, and keep us posted with your progress (and perseverence!), and accompanying pictures of course!

McREBEL

Gold Member

This looks like a fun project for someone who has the time, resources, and know how. I am looking forward to the updates and especially the "It cranked!" post.

OP

The Chicken

Member

OK, The internationals I have owned have a threaded nut inside the outer housing. The nut can float inside the link housing, or can be pinned to make it rigid. Look for a hump around the middle of the link and a hole through the hump for a pin.

I think this might be the case. I see a fat spot on the link and a couple holes, so perhaps that's where the pins go? I will investigate.

What would be the purpose of allowing that link to float?

OP

The Chicken

Member

The leather and brass casing ideas are good ones! That's what I need, some good 'ol farm tech!

I pulled the plugs, looked in the cylinders, didn't see any real rust-some tiny flecks on the valve faces. I squirted a bunch of oil in each hole. I figure after a week or so, I'll pull the plugs and see if it rotates by hand. Supposedly it only sat about a year, so we will see...

I pulled the plugs, looked in the cylinders, didn't see any real rust-some tiny flecks on the valve faces. I squirted a bunch of oil in each hole. I figure after a week or so, I'll pull the plugs and see if it rotates by hand. Supposedly it only sat about a year, so we will see...

OP

The Chicken

Member

OP

The Chicken

Member

Well, the thing was so dirty, I really couldn't even see what was underneath all the oil and dirt. So a few hours here and there with a scraper, several gallons of Super Purple cleaner, and finally a pressure washer revealed a tractor under that crap. Turns out it is yellow!

I did all this while the carb spent a week or two in the carb cleaner bucket. As mentioned, I had also squirted a healthy dose of oil down each cylinder just to make sure nothing would stick. Finally, after several weeks, I had time to mess with it one day, and decided it was time to see if it would turn over by hand. Low and behold, it spins nice and easy! So then I decided to see if it would turn over with the starter. So with the plugs removed, I hooked up a battery and gave it a whirl. Like I had hoped, it turned over easy and squirted whatever excess oil that was still in the cylinders out the hole. Then, as I was cranking it over, I put a finger over each plug hole as just a rough measure to check compression. All seemed functioning except for number two-which was sucking AND blowing with EVERY stroke. Oh-oh... I was afraid that that might be the end of the whole project right there.

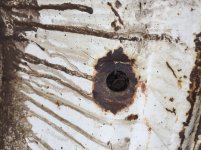

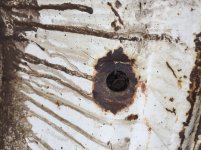

I removed the valve cover to discover this-

Well. THAT can't be good! But the push rod appeared to be straight, the valve easily compressed with light tapping with a rubber mallet, and everything seemed OK. So, with the hopes that perhaps the valve had stuck when we first turned it over, and the extra-loose valve lash just allowed the push rod to fall out, we compressed the spring and stuck the push rod back under the rocker. With fingers crossed, I hit the starter and spun her over a bit (at this point, the carb is still in the cleaner bucket), and it seemed to function just fine.

Then I tightened up the valve lash a bit.

One thing I was concerned with, was during all our cranking activities, I never saw the oil pressure gauge so much as twitch. And after a LOT of cranking, there was only the barest hint of oil showing up at the push rods or in the head area. So I cracked the oil line to the guage and cranked away. Oil started dribbling out of the fitting-so we were getting flow there, at least-although it was not much. A quick squirt of air to the oil gauge line confirmed that the mechanical gauge worked. So I was pretty concerned.

I then decided to dump the old sludge out of the motor and change the filter-which I had ordered from Stieners. I say sludge, because the crap that was in that poor motor could not possibly have been motor oil. I think that oil had not been changed in decades. Then I poured some diesel down the head and out the pan in attempt to flush out any nasties. Then I put new oil in it. When I went to put the new filter on, I encountered the next issue-the filter they sent me was NOTHING like the one that came out of the canister! Luckily, there was a legible (Donaldson, I think) part number on it, and by some great miracle the local NAPA had one that crossed to it. With all that out of the way, it was time to get back to the carb...

I did all this while the carb spent a week or two in the carb cleaner bucket. As mentioned, I had also squirted a healthy dose of oil down each cylinder just to make sure nothing would stick. Finally, after several weeks, I had time to mess with it one day, and decided it was time to see if it would turn over by hand. Low and behold, it spins nice and easy! So then I decided to see if it would turn over with the starter. So with the plugs removed, I hooked up a battery and gave it a whirl. Like I had hoped, it turned over easy and squirted whatever excess oil that was still in the cylinders out the hole. Then, as I was cranking it over, I put a finger over each plug hole as just a rough measure to check compression. All seemed functioning except for number two-which was sucking AND blowing with EVERY stroke. Oh-oh... I was afraid that that might be the end of the whole project right there.

I removed the valve cover to discover this-

Well. THAT can't be good! But the push rod appeared to be straight, the valve easily compressed with light tapping with a rubber mallet, and everything seemed OK. So, with the hopes that perhaps the valve had stuck when we first turned it over, and the extra-loose valve lash just allowed the push rod to fall out, we compressed the spring and stuck the push rod back under the rocker. With fingers crossed, I hit the starter and spun her over a bit (at this point, the carb is still in the cleaner bucket), and it seemed to function just fine.

Then I tightened up the valve lash a bit.

One thing I was concerned with, was during all our cranking activities, I never saw the oil pressure gauge so much as twitch. And after a LOT of cranking, there was only the barest hint of oil showing up at the push rods or in the head area. So I cracked the oil line to the guage and cranked away. Oil started dribbling out of the fitting-so we were getting flow there, at least-although it was not much. A quick squirt of air to the oil gauge line confirmed that the mechanical gauge worked. So I was pretty concerned.

I then decided to dump the old sludge out of the motor and change the filter-which I had ordered from Stieners. I say sludge, because the crap that was in that poor motor could not possibly have been motor oil. I think that oil had not been changed in decades. Then I poured some diesel down the head and out the pan in attempt to flush out any nasties. Then I put new oil in it. When I went to put the new filter on, I encountered the next issue-the filter they sent me was NOTHING like the one that came out of the canister! Luckily, there was a legible (Donaldson, I think) part number on it, and by some great miracle the local NAPA had one that crossed to it. With all that out of the way, it was time to get back to the carb...

OP

The Chicken

Member

So, while all of the shenanigans above were playing out over the course of several weeks, the carb had been sitting in the cleaner. I hadn't intended to soak it that long, life just kept me from getting to it. The good news is that sucker was CLEAN! The bad news is I could barely remember how the **** thing went together!

This was somewhat complicated by the fact that the kit had some extra parts to fit other carbs, along with several different sets of destructions. One thing that i didn't realize is that the throttle shaft is actually sealed by a lip seal-which was totally missing on the carb when I got it. So between the new lip seal, and a couple of o-rings I put on the outside of the shaft that ride in the lip seal retainer, the worn-out throttle shaft seemed at least useable. Which was good, as I really didn't have the time or desire to spend several hours machining parts for a motor I wasn't even sure would run.

Anyway, I got the carb all back together and bolted on. I made a new valve cover gasket from a tired old sheet of cork I happened to have laying around and got that back in place.

At that point, there wasn't much else to do other than see if it would actually run. Concern over the oil pressure (or lack of) had me debating dropping the pan and checking the pump-but I could plainly see that some one had siliconed the pan on at some point and the job was going to be a nasty mess. Plus I was running out of time.

So,.... I put the plugs and wires back on, pulled the choke lever, hit the key and... Would you believe that **** thing rolled over about two revolutions and then fired right up?! Some crud and smoke came out the exhaust, and it coughed once or twice, then commenced to run fairly good. And the oil pressure even decided to make an appearance! Well Ya-Hooo! I shut it down after just a few seconds to check for any major leaks, oil level or to see if there were any new problems that I could see. All looked good, so I fired it right back up. It popped once in awhile until it warmed up and I took the choke off. I went to adjust the idle jet, but ended up putting it back where I had started. I pulled the radiator cap, and water was even moving around after a bit, so it would appear that even the water pump is functioning!

Well, I was on a roll, so why quit now? The front bucket lifted and lowered, scooped and dumped. The tractor went forward and backwards(I only went a foot or so-but I went!), the gannon controls all seemed to function. I am not sure it the 3-point lift is working or not-it is chained up and I didn't seem to get any real movement from it. The biggest bummer was the brakes-there were none!

Now, the hydraulics. Boy, are there some leaks! One front ram is more of a flow than a leak! Several hoses are dripping, every ram seems to leak to one degree or another, the orbital steering valve has a major leak, the manifolds leak, and pretty much every hose except for two little guys should probably be replaced.

It would appear that every single pin and bushing on the machine is worn at best, destroyed at worst.

The gannon is dented and tweaked, and the rear hinge is bound up so that the rear blade won't float up properly.

The hydraulic fluid looks funky and will need changed...

The problems with this poor thing go on and on...

But all-in-all, I am pretty **** excited! The tractor runs, most of the stuff seems to at least function, and I believe this thing is salvagable!

This was somewhat complicated by the fact that the kit had some extra parts to fit other carbs, along with several different sets of destructions. One thing that i didn't realize is that the throttle shaft is actually sealed by a lip seal-which was totally missing on the carb when I got it. So between the new lip seal, and a couple of o-rings I put on the outside of the shaft that ride in the lip seal retainer, the worn-out throttle shaft seemed at least useable. Which was good, as I really didn't have the time or desire to spend several hours machining parts for a motor I wasn't even sure would run.

Anyway, I got the carb all back together and bolted on. I made a new valve cover gasket from a tired old sheet of cork I happened to have laying around and got that back in place.

At that point, there wasn't much else to do other than see if it would actually run. Concern over the oil pressure (or lack of) had me debating dropping the pan and checking the pump-but I could plainly see that some one had siliconed the pan on at some point and the job was going to be a nasty mess. Plus I was running out of time.

So,.... I put the plugs and wires back on, pulled the choke lever, hit the key and... Would you believe that **** thing rolled over about two revolutions and then fired right up?! Some crud and smoke came out the exhaust, and it coughed once or twice, then commenced to run fairly good. And the oil pressure even decided to make an appearance! Well Ya-Hooo! I shut it down after just a few seconds to check for any major leaks, oil level or to see if there were any new problems that I could see. All looked good, so I fired it right back up. It popped once in awhile until it warmed up and I took the choke off. I went to adjust the idle jet, but ended up putting it back where I had started. I pulled the radiator cap, and water was even moving around after a bit, so it would appear that even the water pump is functioning!

Well, I was on a roll, so why quit now? The front bucket lifted and lowered, scooped and dumped. The tractor went forward and backwards(I only went a foot or so-but I went!), the gannon controls all seemed to function. I am not sure it the 3-point lift is working or not-it is chained up and I didn't seem to get any real movement from it. The biggest bummer was the brakes-there were none!

Now, the hydraulics. Boy, are there some leaks! One front ram is more of a flow than a leak! Several hoses are dripping, every ram seems to leak to one degree or another, the orbital steering valve has a major leak, the manifolds leak, and pretty much every hose except for two little guys should probably be replaced.

It would appear that every single pin and bushing on the machine is worn at best, destroyed at worst.

The gannon is dented and tweaked, and the rear hinge is bound up so that the rear blade won't float up properly.

The hydraulic fluid looks funky and will need changed...

The problems with this poor thing go on and on...

But all-in-all, I am pretty **** excited! The tractor runs, most of the stuff seems to at least function, and I believe this thing is salvagable!

OP

The Chicken

Member

So, here is where I could use some help again.

-I seem to recall somewhere that the 3514 industrial tractor was based on another model of IH tractor. Anybody know what that model was? I ask, because a few things dont jive on this, and perhaps if I knew what farm tractor it was based off of, I could clear things up a bit.

-Air cleaner. There was none on it when I got it. And, unfortunately, it looks like it was run without one for a bit(!!!!). I found what I believe to be a valid part number for the dry element-and I can get that locally. But an internet search for the part numbers of the missing wing nut, bottom cup and spacer net me no results. Anybody have an idea where I might look to find these parts? This is where I was thinking that perhaps the farm version of this might help to track down the missing parts.

-Brakes. LIke I said-I don't seem to have any. The service manual I got for the 3514 indicates that the tractor uses a master cylinder/ slave cylinder hydraulic setup-but I have nothing like that. The operators manual I got for it indicates the proper type of brake (looks like a band brake perhaps?) and how to adjust them, but no service details.

-Transmission. The books tell me that there was a hydrostatic OR a clutched 5-speed. But my unit seems to have some features of both. While it is defiantly hydrostatic in the fact that it has seperate forward and reverse pedals, it is missing the dump valve, and I think it might have more than the two speeds a hydrostatic should have.

I am sure I have some more questions, but I am getting tired and need to quit for the night. Thanks again for the help and ideas!

-I seem to recall somewhere that the 3514 industrial tractor was based on another model of IH tractor. Anybody know what that model was? I ask, because a few things dont jive on this, and perhaps if I knew what farm tractor it was based off of, I could clear things up a bit.

-Air cleaner. There was none on it when I got it. And, unfortunately, it looks like it was run without one for a bit(!!!!). I found what I believe to be a valid part number for the dry element-and I can get that locally. But an internet search for the part numbers of the missing wing nut, bottom cup and spacer net me no results. Anybody have an idea where I might look to find these parts? This is where I was thinking that perhaps the farm version of this might help to track down the missing parts.

-Brakes. LIke I said-I don't seem to have any. The service manual I got for the 3514 indicates that the tractor uses a master cylinder/ slave cylinder hydraulic setup-but I have nothing like that. The operators manual I got for it indicates the proper type of brake (looks like a band brake perhaps?) and how to adjust them, but no service details.

-Transmission. The books tell me that there was a hydrostatic OR a clutched 5-speed. But my unit seems to have some features of both. While it is defiantly hydrostatic in the fact that it has seperate forward and reverse pedals, it is missing the dump valve, and I think it might have more than the two speeds a hydrostatic should have.

I am sure I have some more questions, but I am getting tired and need to quit for the night. Thanks again for the help and ideas!

McREBEL

Gold Member

Good to hear it fired off.

Paul Thornton

Gold Member

Looks like you're gaining on it.

robpm

Silver Member

I don't know if you checked out Tractordata on the IH 3514 but if you did not take a look here TractorData.com International Harvester 3514 industrial tractor information It looks like there were a couple of different engines and several different transmissions on this baby. There are a lot of pictures on the web of it and a lot of them show it with a BH. If you hadn't looked at Tractor Data I thought that that might help you some in figuring out the transmission on the one that you have.

Rob

Rob

OP

The Chicken

Member

Yes, I have looked at the tractor data site-Thanks! It seems to only add to the mystery, as it shows 3 different transmissions-and the book I have lists only 2. Could have to do with an eariler revision of the tractor. Mine has a seemingly low serial number of 1390, and the operators manual says for 1695 and up-so that probably isn't helping.

My biggest problems now are no brakes-I am cleaning off the crud to see if I can get the disc brake covers off and perhaps see how they work and what parts I need. I'm hoping it just needs new discs.

Of perhaps a bigger concern is the 3-point lift will not lift or lower. It seems to have no hydraulic power at all. The previous owner had staTED THAT THEY WERE HAVING PROBLEMS WITH IT WHEN IT WAS PARKED. hE SAID IT WOULD SUDDENLY JUST drop at random. I am hoping that the filters are just plugged or something-I really don't want to tear into the lift cover-it looks complex and expensive.

We are cleaning all the crud off now that we have removed the operator station-so perhaps we will be able to see what is going on a little better then.

In the meantime, if anybody has any experience with the brakes or 3-point ion these, I'd really love to hear some input on the subjects.

Thanks again!

My biggest problems now are no brakes-I am cleaning off the crud to see if I can get the disc brake covers off and perhaps see how they work and what parts I need. I'm hoping it just needs new discs.

Of perhaps a bigger concern is the 3-point lift will not lift or lower. It seems to have no hydraulic power at all. The previous owner had staTED THAT THEY WERE HAVING PROBLEMS WITH IT WHEN IT WAS PARKED. hE SAID IT WOULD SUDDENLY JUST drop at random. I am hoping that the filters are just plugged or something-I really don't want to tear into the lift cover-it looks complex and expensive.

We are cleaning all the crud off now that we have removed the operator station-so perhaps we will be able to see what is going on a little better then.

In the meantime, if anybody has any experience with the brakes or 3-point ion these, I'd really love to hear some input on the subjects.

Thanks again!

OP

The Chicken

Member

Well, it's been awhile, and I thought I'd update this, in case anybody is still looking at it.

Let's see, hydraulic fluid. Dear God. this was the worst fluid ever. Seemed like it had a ton of water and dirt in it. Can't really figure out how either got in there, but I do know the filters were not changed anytime recently. The suction filter down on the transmission had imploded and been sucked into pieces it was so plugged up.

These are pics of the suction filter. If you look real close in the second one, you can see how it imploded-basically at that point there was no filter.

This is what the fluid looked like in the bucket. Yuck!

Let's see, hydraulic fluid. Dear God. this was the worst fluid ever. Seemed like it had a ton of water and dirt in it. Can't really figure out how either got in there, but I do know the filters were not changed anytime recently. The suction filter down on the transmission had imploded and been sucked into pieces it was so plugged up.

These are pics of the suction filter. If you look real close in the second one, you can see how it imploded-basically at that point there was no filter.

This is what the fluid looked like in the bucket. Yuck!

OP

The Chicken

Member

So I changed the filters, drained the fluid, tried to flush the transmission as best as I could with some diesel and fresh fluid, then filled it back up.

In the meantime, I had torn a LOT of the rest of the tractor apart. I got the super leaky ram apart, found someone who could get the rebuild kit for it, and about died at the price. 130 bucks per ram for o-rings and rod seals and wipers. Uhhh-no. So I measured everything up and ordered up some o-rings, wipers, and seals for a LOT, LOT less. Should work fine.

Here's the shaft from one of the bucket cylinders with the piston and packing.

As of right now, I have the one all rebuilt and re-installed on the tractor and am just waiting to fire it back up to test that it works.

I had to make my own pin wrench, here it is-

I'm not quite happy with it though-I need to make a hinged one that can wrap further around the locking collar and thus be more stable and apply more torque with out flopping over to the side.

Brakes-Among other things, I found the right book for this tractor, which has helped a TON. Turns out the brakes are double discs which ride on the bull gear shafts and are separated by a friction disc that puts pressure on the discs and outer friction discs vis some little ball bearings. Ordered up some new discs from Steiner, and the thing seems to have brakes now-we'll see when I get to move it again. I also had to replace the shaft seals and o-rings in the seal covers.

At this point I sorta jumped the gun and ordered new tires, thinking I'd have it all done shortly. That was not to be, but it was too late once I had the rims and tires broken down. The old tires were beyond shot. The rims were trashed. Beads all bent, dented, valve stem holes all rusted out-they were used and abused.

The first thing I learned here is those wheel weights are friggin' HEAVY! Thank God I had a forklift!

In the meantime, I had torn a LOT of the rest of the tractor apart. I got the super leaky ram apart, found someone who could get the rebuild kit for it, and about died at the price. 130 bucks per ram for o-rings and rod seals and wipers. Uhhh-no. So I measured everything up and ordered up some o-rings, wipers, and seals for a LOT, LOT less. Should work fine.

Here's the shaft from one of the bucket cylinders with the piston and packing.

As of right now, I have the one all rebuilt and re-installed on the tractor and am just waiting to fire it back up to test that it works.

I had to make my own pin wrench, here it is-

I'm not quite happy with it though-I need to make a hinged one that can wrap further around the locking collar and thus be more stable and apply more torque with out flopping over to the side.

Brakes-Among other things, I found the right book for this tractor, which has helped a TON. Turns out the brakes are double discs which ride on the bull gear shafts and are separated by a friction disc that puts pressure on the discs and outer friction discs vis some little ball bearings. Ordered up some new discs from Steiner, and the thing seems to have brakes now-we'll see when I get to move it again. I also had to replace the shaft seals and o-rings in the seal covers.

At this point I sorta jumped the gun and ordered new tires, thinking I'd have it all done shortly. That was not to be, but it was too late once I had the rims and tires broken down. The old tires were beyond shot. The rims were trashed. Beads all bent, dented, valve stem holes all rusted out-they were used and abused.

The first thing I learned here is those wheel weights are friggin' HEAVY! Thank God I had a forklift!

OP

The Chicken

Member

Here is what the poor rims looked like-

A few hours with a hammer, dolly, and a torch for the bigger dents had the rims looking round again, the bead surfaces acceptable, and looking a bit better overall.

As you can see, the valve stem holes were wasted. Well, I couldn't have THAT! I also wanted to run tubeless tires so that if I got a flat, a simple plug kit would save the day-instaed of an expensive trip to the tire store-which is 50 miles away from where this tractor will eventually reside. Seeing as the rims were welded type, this was a good idea-but first to fix those holes.

Here's what I did-

I had my CNC plasma cutter make me a few square parts with round holes in the middle out of .120 cold roll sheet. Then I carbide reamed the holes to .625". Then I used a hand held plasma cutter to cut out a square with the old worn out hole. A little cleaning up of the cut-out, and then I just welded in the patch piece. Welded it on both sides, the ground down the out side. Good as new!

But I didn't stop there-

I welded on a short piece of 1 1/2" pipe, with a matching female cap (removed in this photo) to protect the valve stem, and act as a secondary seal should the valve stem leak. I really like how it came out.

And here is one with a spankin new tire on it. I sure love the smell of new tires!! These are the biggest shoes I have ever bought!

In case you can't tell, I had the rims powdercoated before the new rubber went on them. This actually created a problem-the new tires and rims look SOOOOO nice, and the rest of the tractor looks sooo hammered. HHMMMMMMM...

A few hours with a hammer, dolly, and a torch for the bigger dents had the rims looking round again, the bead surfaces acceptable, and looking a bit better overall.

As you can see, the valve stem holes were wasted. Well, I couldn't have THAT! I also wanted to run tubeless tires so that if I got a flat, a simple plug kit would save the day-instaed of an expensive trip to the tire store-which is 50 miles away from where this tractor will eventually reside. Seeing as the rims were welded type, this was a good idea-but first to fix those holes.

Here's what I did-

I had my CNC plasma cutter make me a few square parts with round holes in the middle out of .120 cold roll sheet. Then I carbide reamed the holes to .625". Then I used a hand held plasma cutter to cut out a square with the old worn out hole. A little cleaning up of the cut-out, and then I just welded in the patch piece. Welded it on both sides, the ground down the out side. Good as new!

But I didn't stop there-

I welded on a short piece of 1 1/2" pipe, with a matching female cap (removed in this photo) to protect the valve stem, and act as a secondary seal should the valve stem leak. I really like how it came out.

And here is one with a spankin new tire on it. I sure love the smell of new tires!! These are the biggest shoes I have ever bought!

In case you can't tell, I had the rims powdercoated before the new rubber went on them. This actually created a problem-the new tires and rims look SOOOOO nice, and the rest of the tractor looks sooo hammered. HHMMMMMMM...

OP

The Chicken

Member

Now, next is where the whole show almost came to a grinding halt. The 3-point lift. Wow. what a mess.

Thankfully, as I had mentioned, I had finally acquired the proper manual for the tractor, which showed me how to service the lift and all the hydraulic, and mechanical gadgetry that goes with it. Holy crap! There is a bunch of FM that enables that thing to function! If I hadn't been so far into this thing at this point, I might have actually scrapped the project-but the huge investment of new tires had me kind of married to it at this point, so it was do or die.

This broken hydraulic switch (note the nasty fluid/water/dirt) was just the first of the issues hiding under that cover.

I will spare you the details, but once I had this lift cylinder/servo set out of the tractor, it took another 10 HOURS(!!!!) just to get it disassembled!!! Long story short-the contaminated fluid had conspired to seize two little (app. 1/2" bore) sleeve servo valves into their respective bores. Ever try to remove something that sensitive and small from a blind bore? YIKES!! I finally got a tap to thread into the most difficult one, which gave me purchase on it enough to free it up in the bore.

Once the night mare of getting it apart was over, it only took a few hours to thoroughly clean it and reassemble it with all new o-rings.

But when I went to put the rebuilt lift assembly back into the hitch cover, I discovered some more damage that had to be dealt with. So the lift arms and rock shaft had to come out to straighten out some bent parts and replace a few widgets.

This is no fun to work on right here. There is a bunch of stuff you have to work on buried in there that requires a mirror just to see. And there is no room. By the time I got it all back together, my hands were all bruised and cut up from cramming them into this area.

Check out my big shaft!

The good news at this point, is when I got it all back together and fired it up, the 3-point lift seems to work just fine! Which is great, because if it hadn't, I don't know what I'd have done. It remains to be seen it the draft control functions as it should under load-hopefully it does, as adjusting it looks time consuming, difficult, and really hard to do because you have to tear so much stuff apart just to adjust it.

I still have a ton of stuff to do, but at this point I'd say this tractor will live to work again. Stay tuned!

Thankfully, as I had mentioned, I had finally acquired the proper manual for the tractor, which showed me how to service the lift and all the hydraulic, and mechanical gadgetry that goes with it. Holy crap! There is a bunch of FM that enables that thing to function! If I hadn't been so far into this thing at this point, I might have actually scrapped the project-but the huge investment of new tires had me kind of married to it at this point, so it was do or die.

This broken hydraulic switch (note the nasty fluid/water/dirt) was just the first of the issues hiding under that cover.

I will spare you the details, but once I had this lift cylinder/servo set out of the tractor, it took another 10 HOURS(!!!!) just to get it disassembled!!! Long story short-the contaminated fluid had conspired to seize two little (app. 1/2" bore) sleeve servo valves into their respective bores. Ever try to remove something that sensitive and small from a blind bore? YIKES!! I finally got a tap to thread into the most difficult one, which gave me purchase on it enough to free it up in the bore.

Once the night mare of getting it apart was over, it only took a few hours to thoroughly clean it and reassemble it with all new o-rings.

But when I went to put the rebuilt lift assembly back into the hitch cover, I discovered some more damage that had to be dealt with. So the lift arms and rock shaft had to come out to straighten out some bent parts and replace a few widgets.

This is no fun to work on right here. There is a bunch of stuff you have to work on buried in there that requires a mirror just to see. And there is no room. By the time I got it all back together, my hands were all bruised and cut up from cramming them into this area.

Check out my big shaft!

The good news at this point, is when I got it all back together and fired it up, the 3-point lift seems to work just fine! Which is great, because if it hadn't, I don't know what I'd have done. It remains to be seen it the draft control functions as it should under load-hopefully it does, as adjusting it looks time consuming, difficult, and really hard to do because you have to tear so much stuff apart just to adjust it.

I still have a ton of stuff to do, but at this point I'd say this tractor will live to work again. Stay tuned!

Citydude

Super Member

Great work! Yes, please keep us updated. This is fun!

Sent from my iPad using TractorByNet

Sent from my iPad using TractorByNet

Ronaldjaye

Member

Hey chicken, I just want to say I have enjoyed this journey, and I admire you guys who have the guts and talent to take care of your equipment the way you do. Poor me, every time something goes wrong with my stuff I have to take it to the Deere Hospital. Thanks a ton for sharing your experience with us....

DABSGT

Veteran Member

Everything seems to be coming along just fine, nice work. waiting for an its up and running video and some pictures.

Sent from my iPad using TractorByNet

Sent from my iPad using TractorByNet