OP

Ausmac

Silver Member

- Joined

- Nov 16, 2018

- Messages

- 116

- Location

- Proserpine QLD

- Tractor

- Massey Ferguson 188, JD 2130, Fiat 650

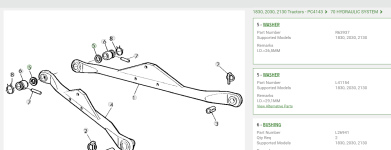

Zebra, the bushing and pin I had trouble with was the centre pin of the mainframe part T21669 and L62839. I had minimal play in my knees so figure I will let them go until I see any wear. I did the same and made a tool to pull them in using some heavy plate and 5/8 booker rod. Yeah I think it is a plug on the rear axle housing, will dump it this morning and see if anything come out. Was thinking maybe it is a low spot in the casting to get rid of all the oil? I can not wait to see what my screen looks like. On here alone people are removing them for the first time. Mine could be the same....