You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post Driver for SA324/424

- Thread starter Lunchbag

- Start date

- Views: 9090

More options

Who Replied?

/ Post Driver for SA324/424

#1

Mark E.

New member

I'll be interested in seeing what others respond with.

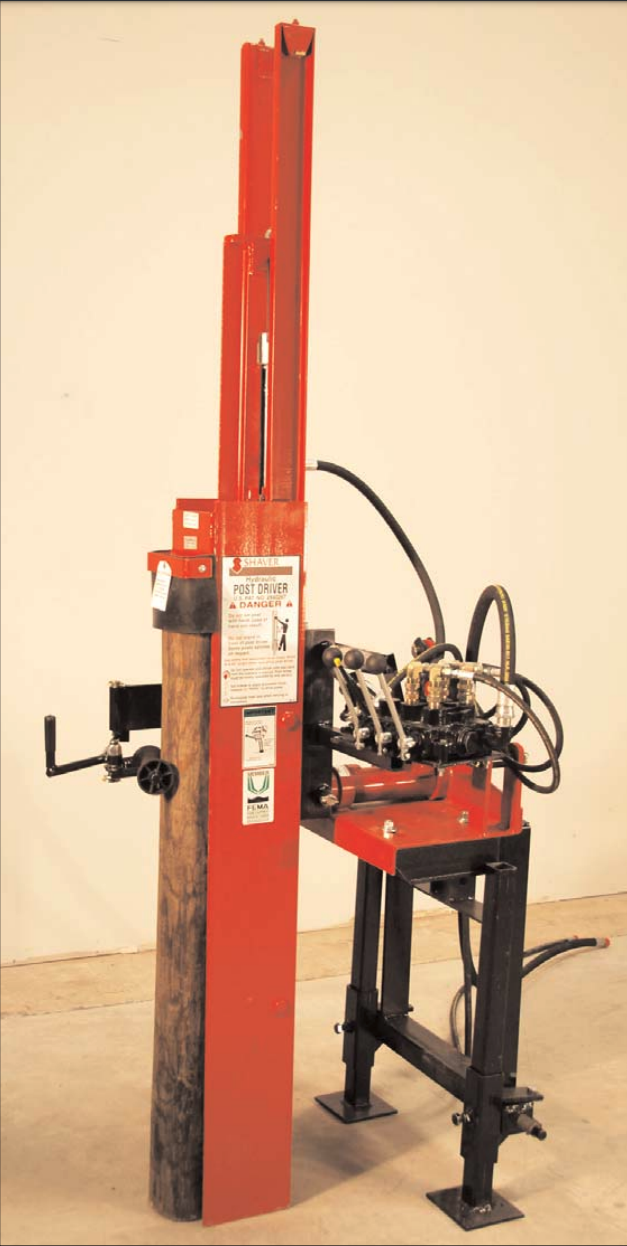

My opinion in based on my experiences with my Worksaver post driver, model HPD-20, 3ph mount. (Not the smallest unit available.)

I have used mine on a Kubota L5030 and a high arch MF165. Majority of my usage has been on the L5030. I also have an SA424 with rear remotes, but I wouldn't consider even trying to mount my post driver on that unit.

I have a number of concerns regarding a 3ph post driver on an SA tractor.

1) The Yanmar is a limited category 1 three point hitch. If you can attach a post driver to the 3ph in the "at rest position", I dont think you would have any ground clearance when Yanmar 3ph is at max lift.

2) The reaction force when the driver is setting posts is in my opinion significant. I would have serious concerns about the Yanmar having enough structure to absorb the shocks and not suffer a casting fracture or other component failure. (My experience driving posts is in clay soils, tough going. However there is always going to be feedback shockwave with each driver drop.)

3) Yanmar hydraulic system flow capacity is 4gpm.

The Worksaver driver I have lists 6-8gpm as the recommended flow rate in the specs. The L5030 has a spec of approximately 10gpm under ideal circumstances for the hydraulic remote flow rate, and it works. I feel it is a little sluggish on the upstroke but spec requirement is met.

It was not my intent to shoot down OPs idea.

I just wanted to share my thoughts based on what I personally have experience with.

If there is a viable implement out there for these size units I would be interested in knowing about it.

My opinion in based on my experiences with my Worksaver post driver, model HPD-20, 3ph mount. (Not the smallest unit available.)

I have used mine on a Kubota L5030 and a high arch MF165. Majority of my usage has been on the L5030. I also have an SA424 with rear remotes, but I wouldn't consider even trying to mount my post driver on that unit.

I have a number of concerns regarding a 3ph post driver on an SA tractor.

1) The Yanmar is a limited category 1 three point hitch. If you can attach a post driver to the 3ph in the "at rest position", I dont think you would have any ground clearance when Yanmar 3ph is at max lift.

2) The reaction force when the driver is setting posts is in my opinion significant. I would have serious concerns about the Yanmar having enough structure to absorb the shocks and not suffer a casting fracture or other component failure. (My experience driving posts is in clay soils, tough going. However there is always going to be feedback shockwave with each driver drop.)

3) Yanmar hydraulic system flow capacity is 4gpm.

The Worksaver driver I have lists 6-8gpm as the recommended flow rate in the specs. The L5030 has a spec of approximately 10gpm under ideal circumstances for the hydraulic remote flow rate, and it works. I feel it is a little sluggish on the upstroke but spec requirement is met.

It was not my intent to shoot down OPs idea.

I just wanted to share my thoughts based on what I personally have experience with.

If there is a viable implement out there for these size units I would be interested in knowing about it.

Thanks, I think those are all the right concerns. I see the Shaver HD-8 model requires only 3-4 gpm so it meets that spec. As far as the lift height, I'm not sure. A photo of the HD-8 makes me think it might be designed for low clearance, but I probably need to get the dimensions to see how many inches I would have to work with.

As for the reaction force, that's my biggest concern because it will be hard to know for sure...until it breaks. I'll discuss it with Shaver to see if any customers are using it on subcompacts or small compacts. But even if they say it is okay, it's hard to know what the effect of those impact forces will be after hundreds of strokes. The ground is pretty sandy, which may help.

As for the reaction force, that's my biggest concern because it will be hard to know for sure...until it breaks. I'll discuss it with Shaver to see if any customers are using it on subcompacts or small compacts. But even if they say it is okay, it's hard to know what the effect of those impact forces will be after hundreds of strokes. The ground is pretty sandy, which may help.

Well, I took the plunge and bought the HD-8 post driver. I'll post some additional info here for anyone else who may be considering this. The plot spoiler is, it works and I feel pretty good about it so far. I just drove my first three posts yesterday so it is too early for a verdict, but I think this could really accelerate my fence building. More to come...

I did a little research before I bought the post driver. I called Shaver and talked to (Adam?) about the limited category 1 concern. He gave me a measurement to verify on my three point hitch, and this made me feel pretty confident that I would have enough clearance.

I also spoke to an experienced mechanic at my local Yanmar dealer about using a post driver on the SA324, and he thought it was reasonable to try a smaller-sized modern post driver with the tractor. He seemed to understand exactly what the concerns were regarding the hydraulic system...the requirements on the supply and return side. And he thought it might not destroy the tractor!

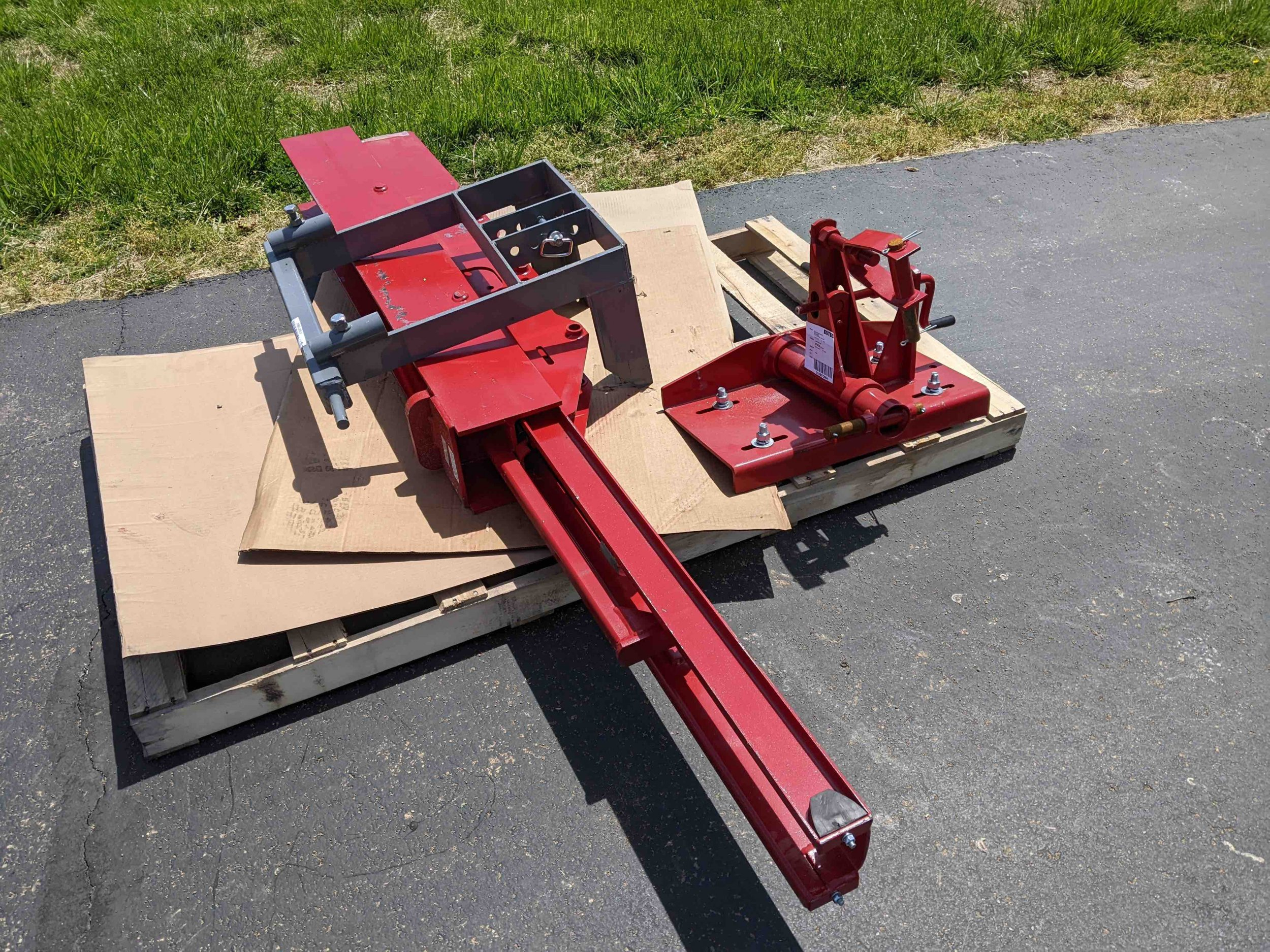

So, I decided to go for it. I couldn't find any used models in good condition. I found the best deal on a new HD-8 at everythingattachments.com in NC. It was just over $3.9k shipped to my house in MD. I thought I was going to need the tractor and pallet forks to get it off the truck, but while I was going for the tractor, the delivery guy maneuvered it onto the lift gate and lowered it to the ground.

The main assembly is long and heavy, and comes on a double size pallet. The paint was badly scraped in places. I signed for it, even though I had no way of knowing I had all the parts. I took pictures of everything. Then I maneuvered the long heavy red piece on the pallet and used the tractor to move it into the garage until I had time to assemble it. Here are some photos from the delivery day. In my next post, I'll talk about putting it together.

I also spoke to an experienced mechanic at my local Yanmar dealer about using a post driver on the SA324, and he thought it was reasonable to try a smaller-sized modern post driver with the tractor. He seemed to understand exactly what the concerns were regarding the hydraulic system...the requirements on the supply and return side. And he thought it might not destroy the tractor!

So, I decided to go for it. I couldn't find any used models in good condition. I found the best deal on a new HD-8 at everythingattachments.com in NC. It was just over $3.9k shipped to my house in MD. I thought I was going to need the tractor and pallet forks to get it off the truck, but while I was going for the tractor, the delivery guy maneuvered it onto the lift gate and lowered it to the ground.

The main assembly is long and heavy, and comes on a double size pallet. The paint was badly scraped in places. I signed for it, even though I had no way of knowing I had all the parts. I took pictures of everything. Then I maneuvered the long heavy red piece on the pallet and used the tractor to move it into the garage until I had time to assemble it. Here are some photos from the delivery day. In my next post, I'll talk about putting it together.

LS Tractor Owner

Super Member

- Joined

- May 1, 2017

- Messages

- 7,665

- Location

- Edgewood, NM

- Tractor

- LS XG3025 TLB, Previously MT125 TLB, Craftsman GTS6500

Nice! They do an amazing job.... I wish I could afford to buy one!

Assembly of the HD-8 took a little time and care. I bolted the base plate to the three-pt hitch mount in my garage. I couldn't do much more in the garage, or it would be too tall to drive out the garage door. I recommend thinking about where you're going to store it before you buy, and make sure you have enough height. I think I measured it at 96". The manual states 88" but this is incorrect. The manual has a lot of outdated info.

I used the tractor and forks to carry the main carriage and ram assembly on the pallet to the tractor shed. Then I swiveled it so I could lift it up high and strap the top to a beam. This allowed me to safely position the main carriage upright for attachment to the section already on the tractor hitch. It wasn't too hard to attach, and I was able to do it alone.

There are two large pins that attach the tilting assembly to the main carriage. You can choose between upper and lower attachment points on the main carriage. The lower ones are apparently for driving 10 ft posts, or for attaching to the front of a small tractor. The upper points worked great for me. I have at least a foot of ground clearance with the 3-pt all the way up. And I can lower it to just fit under the overhang of my shed. I couldn't have asked for a better fit...what a relief!

In the next post, I'll talk about the hydraulics.

I used the tractor and forks to carry the main carriage and ram assembly on the pallet to the tractor shed. Then I swiveled it so I could lift it up high and strap the top to a beam. This allowed me to safely position the main carriage upright for attachment to the section already on the tractor hitch. It wasn't too hard to attach, and I was able to do it alone.

There are two large pins that attach the tilting assembly to the main carriage. You can choose between upper and lower attachment points on the main carriage. The lower ones are apparently for driving 10 ft posts, or for attaching to the front of a small tractor. The upper points worked great for me. I have at least a foot of ground clearance with the 3-pt all the way up. And I can lower it to just fit under the overhang of my shed. I couldn't have asked for a better fit...what a relief!

In the next post, I'll talk about the hydraulics.

MAX-24-Dean

Veteran Member

I am quite interested in how this works out for you.Assembly of the HD-8 took a little time and care. I bolted the base plate to the three-pt hitch mount in my garage. I couldn't do much more in the garage, or it would be too tall to drive out the garage door. I recommend thinking about where you're going to store it before you buy, and make sure you have enough height. I think I measured it at 96". The manual states 88" but this is incorrect. The manual has a lot of outdated info.

I used the tractor and forks to carry the main carriage and ram assembly on the pallet to the tractor shed. Then I swiveled it so I could lift it up high and strap the top to a beam. This allowed me to safely position the main carriage upright for attachment to the section already on the tractor hitch. It wasn't too hard to attach, and I was able to do it alone.

There are two large pins that attach the tilting assembly to the main carriage. You can choose between upper and lower attachment points on the main carriage. The lower ones are apparently for driving 10 ft posts, or for attaching to the front of a small tractor. The upper points worked great for me. I have at least a foot of ground clearance with the 3-pt all the way up. And I can lower it to just fit under the overhang of my shed. I couldn't have asked for a better fit...what a relief!

In the next post, I'll talk about the hydraulics.

View attachment 756787

View attachment 756788

View attachment 756790

View attachment 756791

Yes, after I finish a couple more posts about setting it up and operating it, I'll try to return to this thread in a few days or weeks after I get more actual use from it. It will take some time to be able to judge it fairly.I am quite interested in how this works out for you.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

Far as I'm concerned paint is inconsequential. What rattle cans are for last time I checked.Assembly of the HD-8 took a little time and care. I bolted the base plate to the three-pt hitch mount in my garage. I couldn't do much more in the garage, or it would be too tall to drive out the garage door. I recommend thinking about where you're going to store it before you buy, and make sure you have enough height. I think I measured it at 96". The manual states 88" but this is incorrect. The manual has a lot of outdated info.

I used the tractor and forks to carry the main carriage and ram assembly on the pallet to the tractor shed. Then I swiveled it so I could lift it up high and strap the top to a beam. This allowed me to safely position the main carriage upright for attachment to the section already on the tractor hitch. It wasn't too hard to attach, and I was able to do it alone.

There are two large pins that attach the tilting assembly to the main carriage. You can choose between upper and lower attachment points on the main carriage. The lower ones are apparently for driving 10 ft posts, or for attaching to the front of a small tractor. The upper points worked great for me. I have at least a foot of ground clearance with the 3-pt all the way up. And I can lower it to just fit under the overhang of my shed. I couldn't have asked for a better fit...what a relief!

In the next post, I'll talk about the hydraulics.

View attachment 756787

View attachment 756788

View attachment 756790

View attachment 756791

Before I installed the post driver, I had a dual rear remote valve installed by the Yanmar dealer. The mechanic and I discussed that a power beyond was really the ideal way to power a post driver, but I decided to get the dual remote valve instead, in case I want it for other stuff in the future. The downside is, I have to rig the lever up or down while operating the post driver, and accept a slightly lower flow rate. But it worked fine during my trial run, so I think I'm happy with the decision.

Shaver provided all three hoses needed for the HD-8, and the fittings to connect them to the control valve on the driver. I had to purchase a quick disconnect fitting to connect the supply hose to the remote valve, and also an adapter to connect the discharge hose to the hydraulic tank (in place of the cap).

Shaver offers adapters for various tractor models, but when I talked to them their list only had the old Yanmar model numbers, so I didn't buy one. The Yanmar mechanic knew exactly what I needed and called around locally to find an adapter. One end has male threads which match the hydraulic reservoir fill port, and the other end has female threads for a 3/4" hydraulic fitting. I also used a 3/4" 90 deg bend with swivel to attach to the discharge hose.

There wasn't quite enough clearance above the fill port to install these, so I trimmed a little metal to make them fit. See the pictures below. In the next post, I'll cover operating it.

Shaver provided all three hoses needed for the HD-8, and the fittings to connect them to the control valve on the driver. I had to purchase a quick disconnect fitting to connect the supply hose to the remote valve, and also an adapter to connect the discharge hose to the hydraulic tank (in place of the cap).

Shaver offers adapters for various tractor models, but when I talked to them their list only had the old Yanmar model numbers, so I didn't buy one. The Yanmar mechanic knew exactly what I needed and called around locally to find an adapter. One end has male threads which match the hydraulic reservoir fill port, and the other end has female threads for a 3/4" hydraulic fitting. I also used a 3/4" 90 deg bend with swivel to attach to the discharge hose.

There wasn't quite enough clearance above the fill port to install these, so I trimmed a little metal to make them fit. See the pictures below. In the next post, I'll cover operating it.

LS Tractor Owner

Super Member

- Joined

- May 1, 2017

- Messages

- 7,665

- Location

- Edgewood, NM

- Tractor

- LS XG3025 TLB, Previously MT125 TLB, Craftsman GTS6500

You could get a "detent" put in one of the remotes. That way it 'locks' in place, holding the valve open.

Cool, I didn't know that.You could get a "detent" put in one of the remotes. That way it 'locks' in place, holding the valve open.

Torvy

Super Member

I'm curious if this is specifically a Yanmar problem or just the same problem with any SCUT or small CUT? Does Yanmar have some unique 3pt hitch feature?

Well, I'm sorry for taking so long to report back on what I've learned about operating the Shaver HD-8 on the SA-324. It has been a long learning process, and it has included some frustration along the way. I'll try to make a few useful posts (pun intended) over the next few days to share what I've learned. But I can summarize the main points up front:

First, I no longer have any qualms about using the SA-324 to operate the HD-8. I feel like it is a pretty good match. The issues I've encountered have more to do with the post driver than the tractor.

I'll summarize the main learning points here:

- Wait for good soil conditions. You may have to set it aside for months (i.e. - during summer) before the soil is soft enough to make good progress.

- Use the "storage jacks" to stabilize it when pounding. Just like the manual says not to.

- Keep replacement springs on hand.

- Accept "good enough." Don't expect to get the posts perfectly aligned, like when you set them the old-fashioned way. But you will move faster.

- Single person operation works fine.

More details to follow.

First, I no longer have any qualms about using the SA-324 to operate the HD-8. I feel like it is a pretty good match. The issues I've encountered have more to do with the post driver than the tractor.

I'll summarize the main learning points here:

- Wait for good soil conditions. You may have to set it aside for months (i.e. - during summer) before the soil is soft enough to make good progress.

- Use the "storage jacks" to stabilize it when pounding. Just like the manual says not to.

- Keep replacement springs on hand.

- Accept "good enough." Don't expect to get the posts perfectly aligned, like when you set them the old-fashioned way. But you will move faster.

- Single person operation works fine.

More details to follow.

MAX-24-Dean

Veteran Member

Thanks for posting your update.Well, I'm sorry for taking so long to report back on what I've learned about operating the Shaver HD-8 on the SA-324. It has been a long learning process, and it has included some frustration along the way. I'll try to make a few useful posts (pun intended) over the next few days to share what I've learned. But I can summarize the main points up front:

First, I no longer have any qualms about using the SA-324 to operate the HD-8. I feel like it is a pretty good match. The issues I've encountered have more to do with the post driver than the tractor.

I'll summarize the main learning points here:

- Wait for good soil conditions. You may have to set it aside for months (i.e. - during summer) before the soil is soft enough to make good progress.

- Use the "storage jacks" to stabilize it when pounding. Just like the manual says not to.

- Keep replacement springs on hand.

- Accept "good enough." Don't expect to get the posts perfectly aligned, like when you set them the old-fashioned way. But you will move faster.

- Single person operation works fine.

More details to follow.

Just went throught the waiting for good soil conditions here. Probably could have got a hundred in with a pounder, but my tractor doesn't have the ground clearance to have one.

I like your setup.

The most frustrating part about using the HD-8 has been getting the posts to go in straight.

First, it takes a little time to get the tractor in exactly the right spot with the post driver vertical in both axes, and because I'm working alone that means getting on and off the tractor a couple of times. No big deal.

But when pounding the posts, I found the driver tended to lean either left or right after being aligned vertically. It did not move at all in the fore-aft direction. It seems there is some freeplay in the left-right direction. The freeplay isn't in the driver itself, but in the three point hitch. Tightening the turnbuckles on the lower arms did not fix it.

The manual says you should only have the foot of the driver (calls it the "stabilizer") on the ground when driving the posts, and not the storage jacks. However all the videos online show the storage jacks in the down position when driving (even the Shaver videos show this). So I tried it with the storage jacks down and it improved things a lot. It essentially took out the left-right sway tendency.

However, there can still be some left-right error in the posts, even if the driver stays upright. For unknown reasons, the posts just like to wander a bit. I think by using the storage jacks I took out about half of the total error in post alignment. I can't get them perfect like I used to when setting them by hand. Disappointing, but I can go much faster without beating myself up, which is very helpful.

I have the manual tilting model, which seems fine to me. The model with hydraulic tilt cost 50% more, and that would not be worth it to me. The 15% tilt capacity has been just enough for me. I've been able to handle some pretty good slopes. I've maxed it out once. I use a regular carpenter level against the frame to get it level in both directions.

First, it takes a little time to get the tractor in exactly the right spot with the post driver vertical in both axes, and because I'm working alone that means getting on and off the tractor a couple of times. No big deal.

But when pounding the posts, I found the driver tended to lean either left or right after being aligned vertically. It did not move at all in the fore-aft direction. It seems there is some freeplay in the left-right direction. The freeplay isn't in the driver itself, but in the three point hitch. Tightening the turnbuckles on the lower arms did not fix it.

The manual says you should only have the foot of the driver (calls it the "stabilizer") on the ground when driving the posts, and not the storage jacks. However all the videos online show the storage jacks in the down position when driving (even the Shaver videos show this). So I tried it with the storage jacks down and it improved things a lot. It essentially took out the left-right sway tendency.

However, there can still be some left-right error in the posts, even if the driver stays upright. For unknown reasons, the posts just like to wander a bit. I think by using the storage jacks I took out about half of the total error in post alignment. I can't get them perfect like I used to when setting them by hand. Disappointing, but I can go much faster without beating myself up, which is very helpful.

I have the manual tilting model, which seems fine to me. The model with hydraulic tilt cost 50% more, and that would not be worth it to me. The 15% tilt capacity has been just enough for me. I've been able to handle some pretty good slopes. I've maxed it out once. I use a regular carpenter level against the frame to get it level in both directions.

I was able to drive most of them in straight this weekend. The difference was probably the wet conditions we have had recently. The ones that went in the easiest were also the straightest. The manual says, "Posts will drive into the ground much straighter using shorter strokes." I agree with this. But you can't use short strokes if you have hard ground. It's really more about ground conditions than technique.

On springs and things:

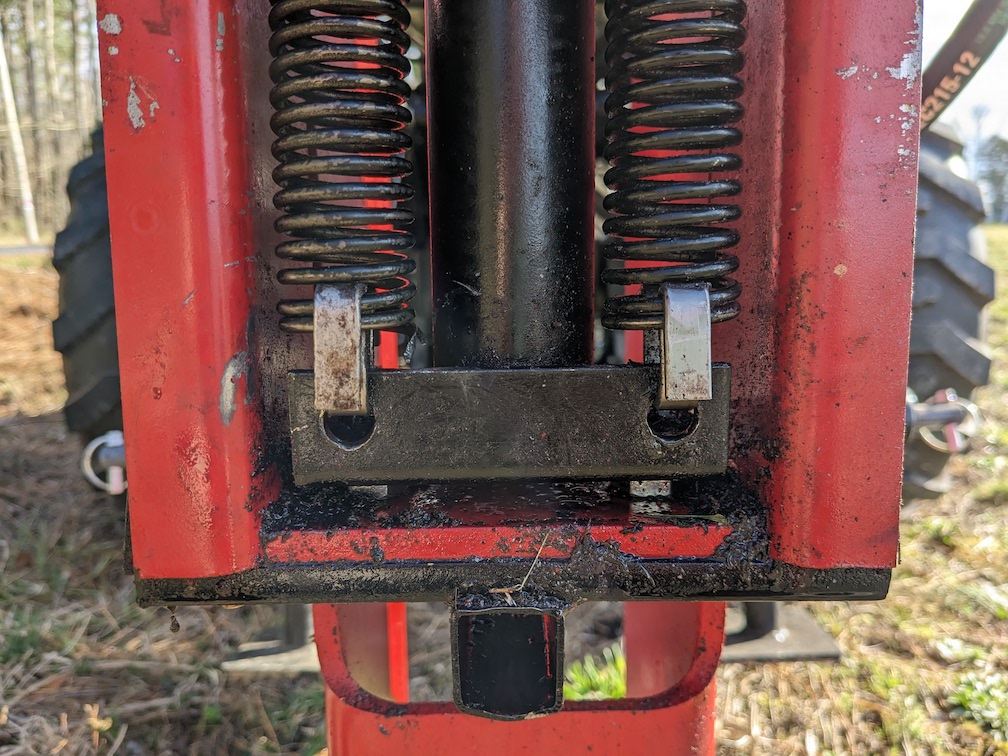

The second biggest frustration with the HD-8 has been the springs.

The driver incorporates two long extension springs which, together with gravity, accelerate the ram downward to strike the post. You can imagine how I felt when the first spring broke while driving the 19th post, and the second spring broke while driving the 21st post.

I called Shaver because I imagined the springs should last much longer, but Shaver said the springs are not included in the warranty. They also reminded me that the springs need to be seasoned every day before use by cycling them 10-15 times. Yes, I did this every time. So, I bought replacements from the same dealer I bought the driver from, at $50 a piece, and I hoped the replacements would last longer.

They did - one lasted for the next 93 posts, and another for 100. Also, because the springs were breaking at the curved hook at the bottom, I bought some clips which are designed for a previous type of springs, and fastened them to the bottom of the broken springs to get some more use out of them before replacement. That worked for a while, but eventually they broke in other places and had to be replaced again. This time the dealer told me they no longer sold any Shaver equipment. So I found another supplier, but the springs were now $70 each plus $30 shipping.

By the way, most of the broken springs stayed in the channel when they broke, but two of them shot out the top. One of those landed draped across the hydraulic lines and did no damage, and the other flew up and over the tractor and landed between the hood and the bucket. It also did no damage, but one end of the spring plugged itself 2" in the dirt, so I was glad it didn't hit the hood. Or my head.

Replacing the springs is easy, as long as you don't follow the instructions in the manual. The manual tells you to disassemble and reassemble the post driver for spring replacement. This is baffling, since you can figure out how to replace them in the field and it only takes five minutes. You can also install a spring clip to repair the bottom of a broken spring pretty easily in the field. You definitely want a spare set of springs at all times. It is frustrating to lose days waiting on replacements.

So, why did the first springs break so early? For a long time I assumed they were from a bad lot, but I don't believe that anymore. Here's my theory. Most of the fatigue on the metal spring occurs at impact. That impact force is proportionate to the rate of deceleration, which is proportionate to the deformation distance (how much the post moves). So the impact force will double if deformation distance is halved.

So the long and short of it is, not only will poor soil conditions require more strikes on the post, but each strike will fatigue the springs more quickly. You can see how bad conditions quickly become a recipe for broken springs.

Another thing you can do to avoid over-fatiguing your springs is to quit when you are close enough. For example, if I am trying to drive the posts 42" into the ground, but progress slows dramatically near the end, as long as I have at least 36" in the ground, I quit and cut off the top of the post to fit. This saves time, frustration, and springs. I'm currently on my third pair of springs, and I'm up to 115 posts with this pair, with no breakage.

The second biggest frustration with the HD-8 has been the springs.

The driver incorporates two long extension springs which, together with gravity, accelerate the ram downward to strike the post. You can imagine how I felt when the first spring broke while driving the 19th post, and the second spring broke while driving the 21st post.

I called Shaver because I imagined the springs should last much longer, but Shaver said the springs are not included in the warranty. They also reminded me that the springs need to be seasoned every day before use by cycling them 10-15 times. Yes, I did this every time. So, I bought replacements from the same dealer I bought the driver from, at $50 a piece, and I hoped the replacements would last longer.

They did - one lasted for the next 93 posts, and another for 100. Also, because the springs were breaking at the curved hook at the bottom, I bought some clips which are designed for a previous type of springs, and fastened them to the bottom of the broken springs to get some more use out of them before replacement. That worked for a while, but eventually they broke in other places and had to be replaced again. This time the dealer told me they no longer sold any Shaver equipment. So I found another supplier, but the springs were now $70 each plus $30 shipping.

By the way, most of the broken springs stayed in the channel when they broke, but two of them shot out the top. One of those landed draped across the hydraulic lines and did no damage, and the other flew up and over the tractor and landed between the hood and the bucket. It also did no damage, but one end of the spring plugged itself 2" in the dirt, so I was glad it didn't hit the hood. Or my head.

Replacing the springs is easy, as long as you don't follow the instructions in the manual. The manual tells you to disassemble and reassemble the post driver for spring replacement. This is baffling, since you can figure out how to replace them in the field and it only takes five minutes. You can also install a spring clip to repair the bottom of a broken spring pretty easily in the field. You definitely want a spare set of springs at all times. It is frustrating to lose days waiting on replacements.

So, why did the first springs break so early? For a long time I assumed they were from a bad lot, but I don't believe that anymore. Here's my theory. Most of the fatigue on the metal spring occurs at impact. That impact force is proportionate to the rate of deceleration, which is proportionate to the deformation distance (how much the post moves). So the impact force will double if deformation distance is halved.

So the long and short of it is, not only will poor soil conditions require more strikes on the post, but each strike will fatigue the springs more quickly. You can see how bad conditions quickly become a recipe for broken springs.

Another thing you can do to avoid over-fatiguing your springs is to quit when you are close enough. For example, if I am trying to drive the posts 42" into the ground, but progress slows dramatically near the end, as long as I have at least 36" in the ground, I quit and cut off the top of the post to fit. This saves time, frustration, and springs. I'm currently on my third pair of springs, and I'm up to 115 posts with this pair, with no breakage.

MAX-24-Dean

Veteran Member

Its good that you figured out the spring fatigue work around so the springs last longer.

It is post installation time here as the ground moisture content is about right for digging posts. In the time you installed (pounded) your 200 plus posts, I have gotten 16 done by hand. Thankfully that is all I need to complete.

Good update on your progress!

It is post installation time here as the ground moisture content is about right for digging posts. In the time you installed (pounded) your 200 plus posts, I have gotten 16 done by hand. Thankfully that is all I need to complete.

Good update on your progress!

Here are some similar links:

- Replies

- 7

- Views

- 3K