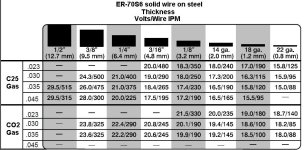

Mike, here's a clarified version of the chart from my MM252, maybe you can get an idea from that - but before it's gonna mean much, you will need to "calibrate" voltage and wire speed - otherwise those knobs won't tell you much unless you wanna keep a notebook like "got best results with .023 wire on 1/8" steel with knobs set at 2 and 5", etc -

Another option - if your manual tells you more about what those knobs mean, the chart below should help - otherwise, keep reading -

With the "calibration" method, you would first disconnect the drive roll so wire doesn't feed - it should still be "hot" when you squeeze the trigger tho, then with a volt meter between ground lead and the mig wire, you should be able to read the voltage at each # on the knob and write those down ("1=16volts", etc...) In reality tho, those will be "open circuit" voltage; in use, the voltage will probably be a bit less.

To calibrate wire speed you would hook the drive roll back up so it feeds - then, starting with wire just barely sticking out of the tip, set the feed knob to "1", squeeze the trigger for EXACTLY 6 seconds and stop - measure the length of wire (in inches) and multiply by 10 - that is your IPM at "1" - repeat for each knob setting til you have a chart of wire speeds at each knob #.

From there, hopefully your LWS carries the Miller "slide rule" Mig calculators, they're only a few bucks - it's a physical version of the chart found here, only better

MIG Solid-Core Welding Calculator - MillerWelds

Hopefully this will give you an idea - personally, with that welder I'd consider just sticking to .030 wire - I've welded 18 gauge with mine using C25 gas and .035 wire, .030 should take you down even thinner... Steve