rogerius

Silver Member

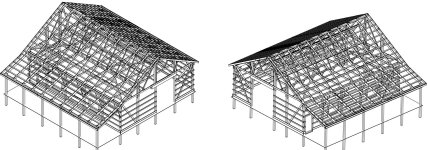

After two years of indecision, last week we start building our pole barn. I was looking for a while for somebody to build for us at a reasonable cost but didn't find. The quotes which i received were everywhere from 28k to 58k; yes, 58K. Based on this we decided to build it ourselves and we started last week. It'll be a 32'x40', 11' tall with a lean on one side with 2 garage doors, service door and windows.

How I mentioned already, we started last week and mother nature cooperated with us: no wind, no rain an ideal weather to build. The lumber was delivered as promised and was 4000$CAD. Very impress with a supplier as we found one pole cracked and they replaced in the same day even they are located at 60Km away from us.

Working with my son couple days and then with my wife, I consider that we did a lot for 5 days of work. We are able to drill 24 holes with a 18" auger, pour the footings(we mixed in a wheelbarrow around 90 bags of cement), align, and install the poles, attached the girds and one side of header plated.

Being weekend warriors we are going back this weekend to finalize the framing as the trusses will be delivered in two weeks at a cost of 1600CAD, and the metal with garage doors at 5000CAD. If I'm adding all the costs without our labour, the total will be around 11K, so not sure how somebody can justify 28K or 58K for this barn

Here are couple pictures and more will follow.

How I mentioned already, we started last week and mother nature cooperated with us: no wind, no rain an ideal weather to build. The lumber was delivered as promised and was 4000$CAD. Very impress with a supplier as we found one pole cracked and they replaced in the same day even they are located at 60Km away from us.

Working with my son couple days and then with my wife, I consider that we did a lot for 5 days of work. We are able to drill 24 holes with a 18" auger, pour the footings(we mixed in a wheelbarrow around 90 bags of cement), align, and install the poles, attached the girds and one side of header plated.

Being weekend warriors we are going back this weekend to finalize the framing as the trusses will be delivered in two weeks at a cost of 1600CAD, and the metal with garage doors at 5000CAD. If I'm adding all the costs without our labour, the total will be around 11K, so not sure how somebody can justify 28K or 58K for this barn

Here are couple pictures and more will follow.