ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 32,246

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Do the same weld on the back side as you did on this one (both welded) and hit it, the material will bend before the weld breaks (most likely).

Yeah, most definitely. Actually I think a proper weld and the 1/4" material would bend even if only welded on one side.

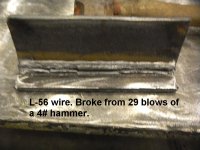

What I tried to do was duplicate Shield Arc's example to show the difference in a proper weld and an inadequate weld.

I could do that weld again and based on the weaknesses I see in this example, produce a stronger weld. I didn't get anywhere near enough penetration and my bead is too small. Not enough thickness in the center of the bead to produce strength.