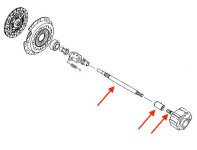

Last week I got the new shaft for the pump:

View attachment 678212

From this:

View attachment 678213

To this:

View attachment 678214

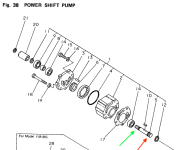

I rebuild the tractor, put a new hydraulics filter on it and added new oil in the transmission/hydraulics reservoir.

At first the tractor seemed to work 100%, but after a while the powershift give some issues, it wont shift in the reverse and 1st gear.

Sometimes it won't shift and sometimes it takes up to 30 seconds and then it shifts into gear.

I suspect it has too little oil in it.

Got 10 liters, filled the filter first and the put the rest in the reservoire.

The manual says it need 8 liters, but I think it needs way more.

Anyone over here who knows how many liters oil this tractor needs?