scott_vt

Super Member

- Joined

- Oct 5, 2004

- Messages

- 7,771

- Location

- east wells,vt

- Tractor

- 1986 MF 1040, 1942 Farmall A, 1949 Farmall Super A

Mornin Larry,

Looks like you have come up with a great idea ! And with Robs help Im sure it will turn into reality ! Glad to see you guys hooked up and put your collective minds to work together !

Reading through the thread, I thought I was serving my apprenticeship allover again

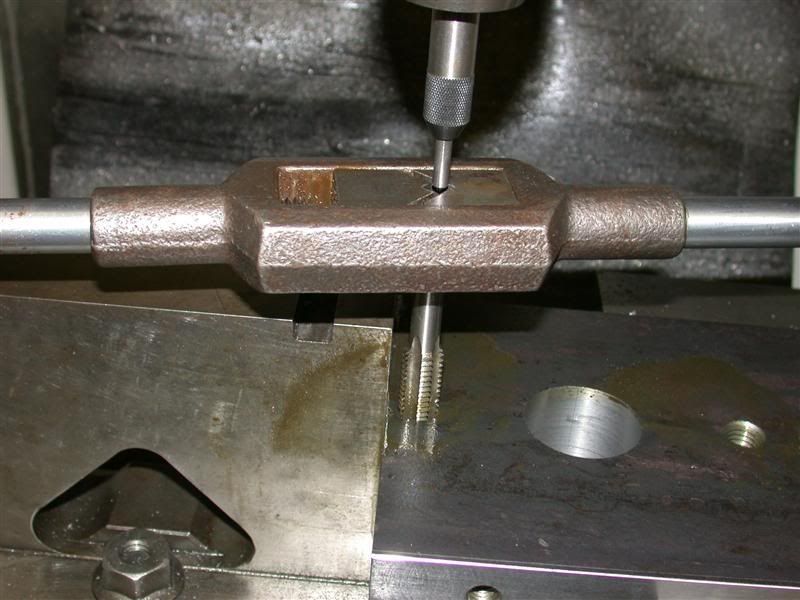

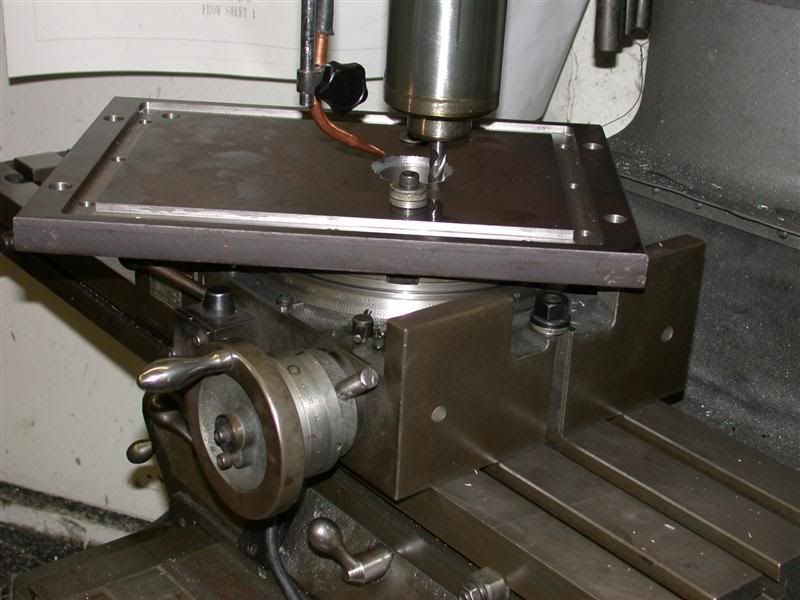

One question on the keyway you broached. Couldnt you find anyone with a hydraulic press ? All you really needed to do was make a plug to fit the bore on your lathe, mill a keyway through the plug and use a keyway broach with shim stock for progressively deeper cuts !

Great thread, and I will be following along!

Looks like you have come up with a great idea ! And with Robs help Im sure it will turn into reality ! Glad to see you guys hooked up and put your collective minds to work together !

Reading through the thread, I thought I was serving my apprenticeship allover again

One question on the keyway you broached. Couldnt you find anyone with a hydraulic press ? All you really needed to do was make a plug to fit the bore on your lathe, mill a keyway through the plug and use a keyway broach with shim stock for progressively deeper cuts !

Great thread, and I will be following along!