Thanks. Yeah Youtube said many of the same things about the needles. The bit about adding grease makes perfect sense too. I looked at what I have in this yoke assembly and they have clips on the inside of the joint. May not be as easy to get to, but I know what to do now. Are you also on Welding Web with the same handle...or Practical Machinist? I know you have been here a long time but your tag sounds familiar from elsewhere, too.

So I may have finally found a decent solution to the problem of mating the pump to the driveshaft. I asked about suppliers of spline parts on PM and one of the replies was for these guys:

G&G Manufacturing Company

They have a decent catalog with a lot of options. It helped me learn and sort through the world of driveshafts and adapters (which as you can see I am new to). Well they have this system Called "Weldajoint" or something that allows you to build up a shaft from components if you just weld together the various items. More importantly they have a hub adapter system that might solve all my problems. They list a ton of bushings for all sorts of shafts that can be welded to their hub adapter so you can mate 2 different shafts pretty easily.

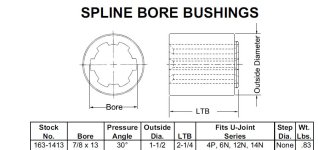

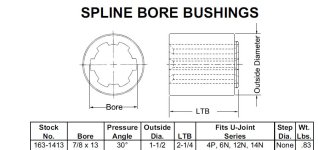

So this looks like the bushing that will fit the pump's 13 tooth spline (ignore picture, it is a different configuration, but just gives the idea):

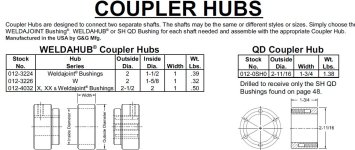

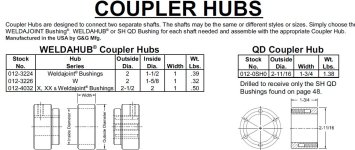

Then I get the first coupler/hub in this table:

And then just figure out what I need on the other side of the coupler hub and weld it all up. Best case I can use the 3/4x7/8 shaft on the driveshaft right now. Worst case it does not reach and I replace that half of the yoke/shaft with something that does reach and use that. Kind of an important weld as I don't have anything to try it out on first to set parameters and I am not some pro welder, so I need to dial things in first, but I bet I can get there.

I am also thinking of a bearing at the end to support the end of the driveshaft where it meets the pump. But that is a ways off for now. Just one of the many things taking up space in my head about this...