dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,594

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

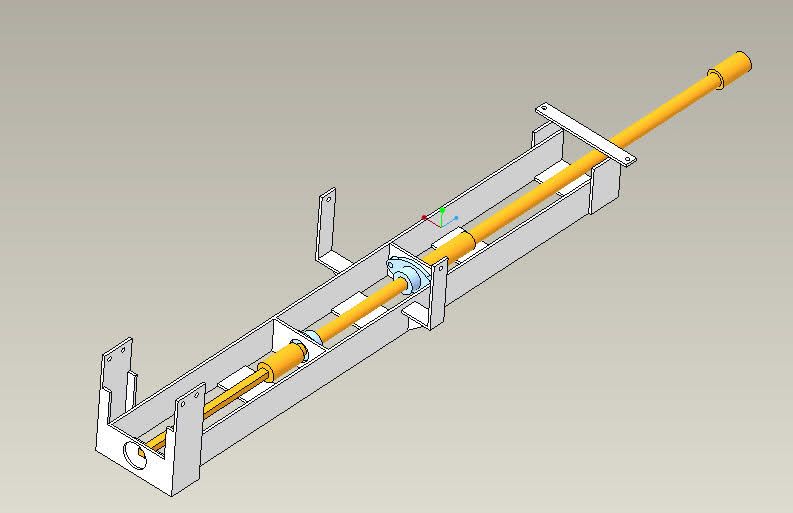

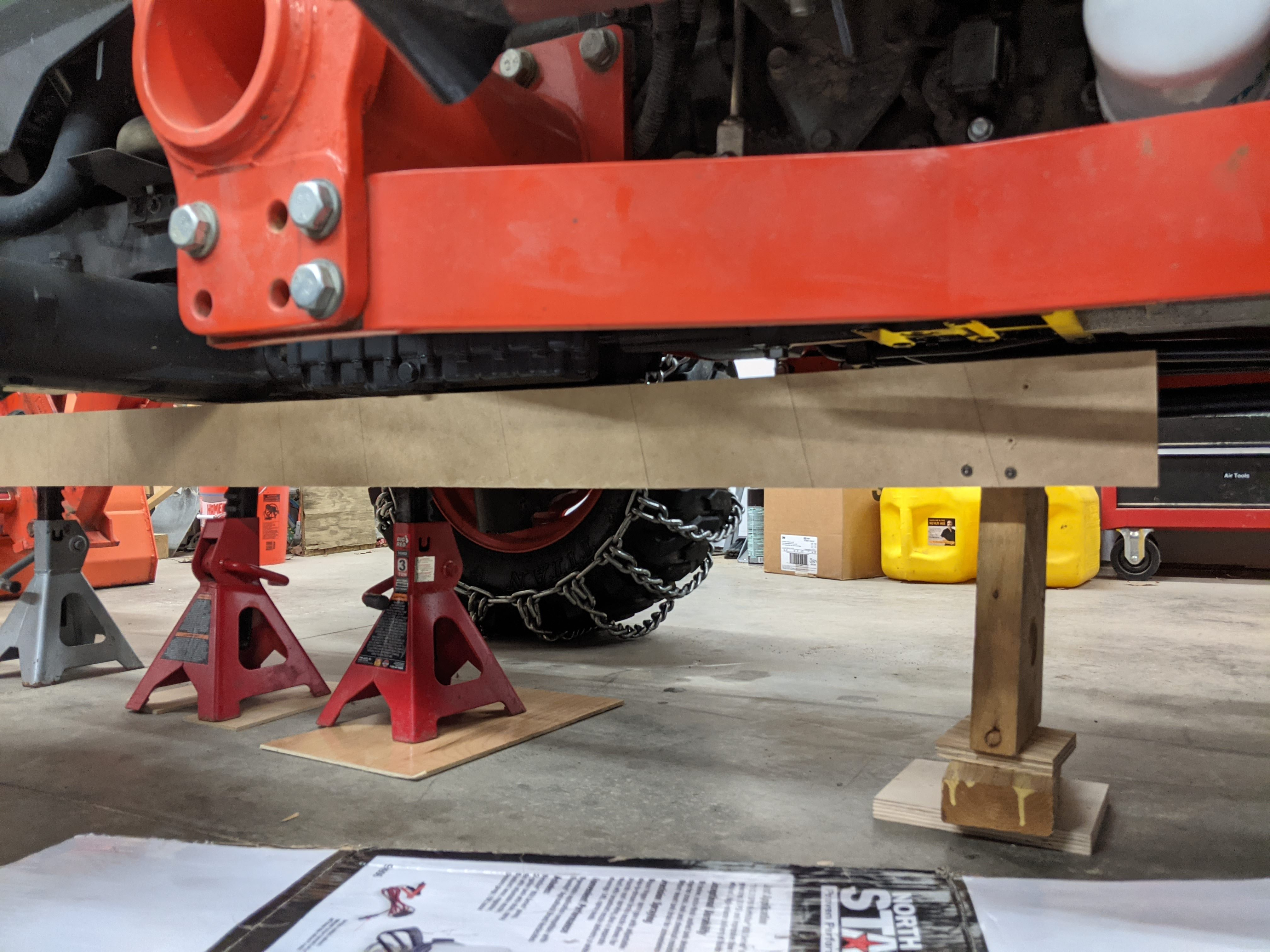

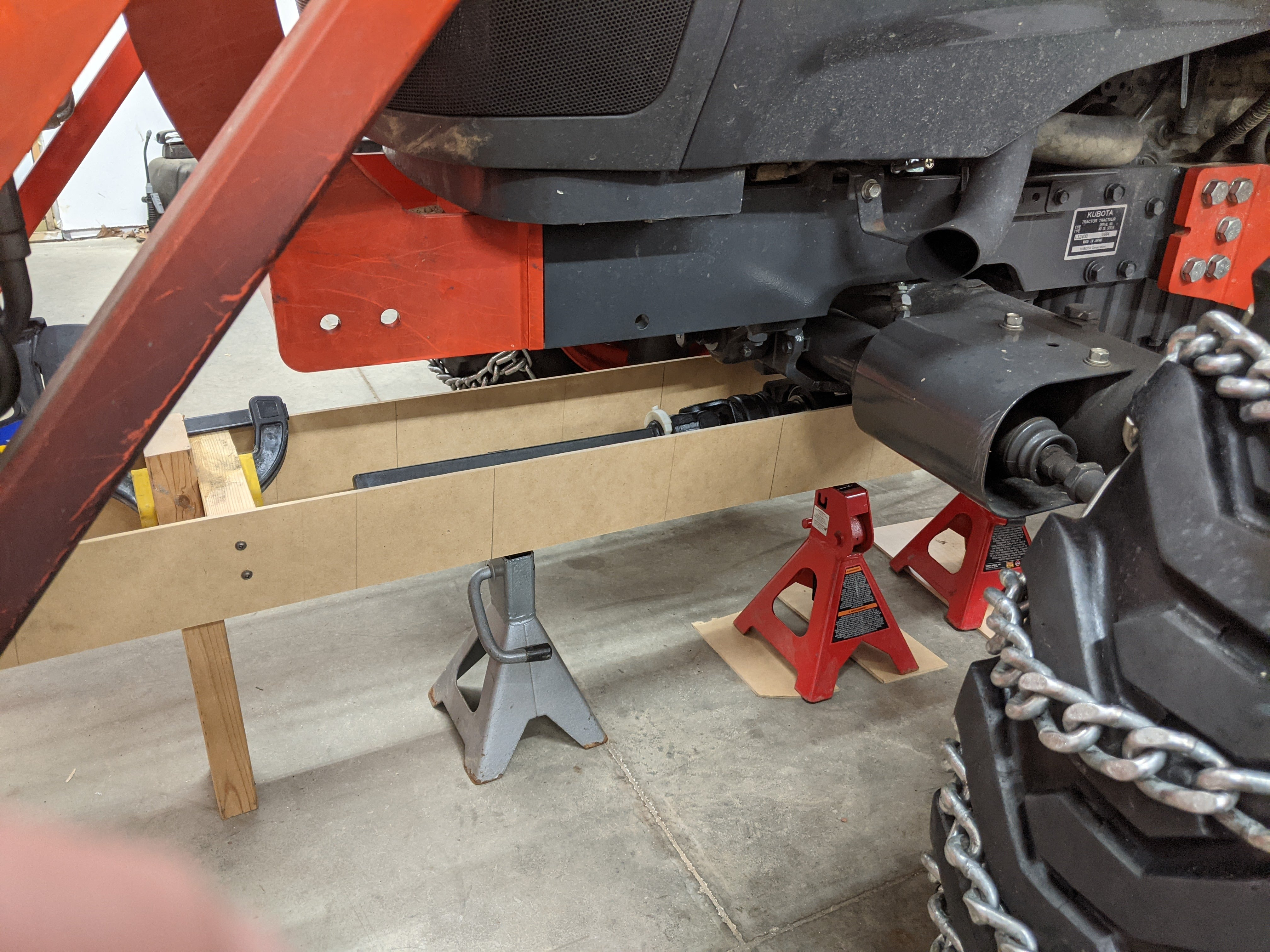

I refined my CAD model a bit and added the bearings. Actually I have changed it a bit since I took that screen shot, but, meh, close enough. I also made a mock-up out of hardboard and 2x4 blocks to see better how it fits. I can see i will need some relief around the axle so it can pivot and not bind up on the rails.

Looks like I am ready to order up some steel Mon AM. One full 20' stick of 4" x 5/16" is going to make up the bulk of this thing. I'll need some other bits beyond that like some 2" wide flat bar but first things first. The steel place is close so no big deal making an extra trip or two. So I can rough out the basic frame and see what else I need so I don't buy stuff I won't need.

Looks like I am ready to order up some steel Mon AM. One full 20' stick of 4" x 5/16" is going to make up the bulk of this thing. I'll need some other bits beyond that like some 2" wide flat bar but first things first. The steel place is close so no big deal making an extra trip or two. So I can rough out the basic frame and see what else I need so I don't buy stuff I won't need.