montejw

Gold Member

thingy, I'm not saying I know it all, or very much, I've just been looking at welders for bit, want to buy one, trying to figure out which so I do a lot of reading. Here's a bit from Lincoln about their Ranger 250:thingy said:Monte,never seen a welder that had written on it,downhill,,,but that don't mean everything,,,can't see how having it wrote on anything would help,,different people run different amps,and it would change depending on what sized rod or wire you was using,,, Downhill is just a direction used on vertical position,,instead of starting at bottom and welding up,,in downhill you start at top and weld down. Yeah,generally a higher heat is used,,you generally carry less metal and travel faster as well,,real good for thin stuff,,,but if you have the technique down you can weld thicker stuff with it as well,and make just as good a weld. Two different worlds when it comes to pipe welding though,,,up,,powerplants,,down,pipelines.

Now its different than under water welding,,thats where somebody holds a cup of water over your head while you weld,,,,man I'm funny,,,thingy

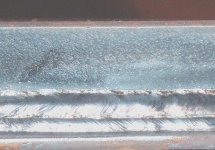

"The Ranger® 250 is ready for a workout – all day, everyday! Intended for contractors, construction and maintenance applications, this tough Lincoln gasoline-driven welder/generator delivers 250 amps for welding at 100% duty cycle. The Ranger 250 is recommended for stick welding, including a separate, dedicated downhill pipe mode, as well as Touch-Start™ DC TIG, flux-cored and MIG wire welding and arc gouging. Lincoln Chopper Technology provides easy starts, an extremely smooth arc, low spatter and outstanding bead appearance. The sleek, enclosed case lowers noise and protects critical engine components. Hot looks, hot features, hot performance – That’s the Ranger 250!"

I've seen others with the downhill mode too. Not sure what it means, and it might just not mean anything at all, it's just something I've read. Maybe it's just a Lincoln thing they make to sound good.

Monte